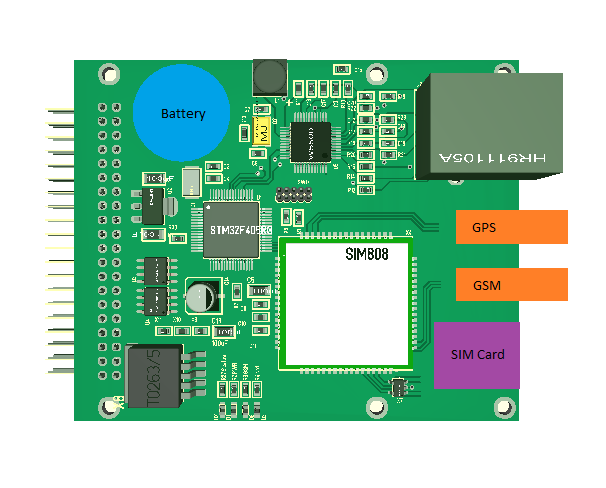

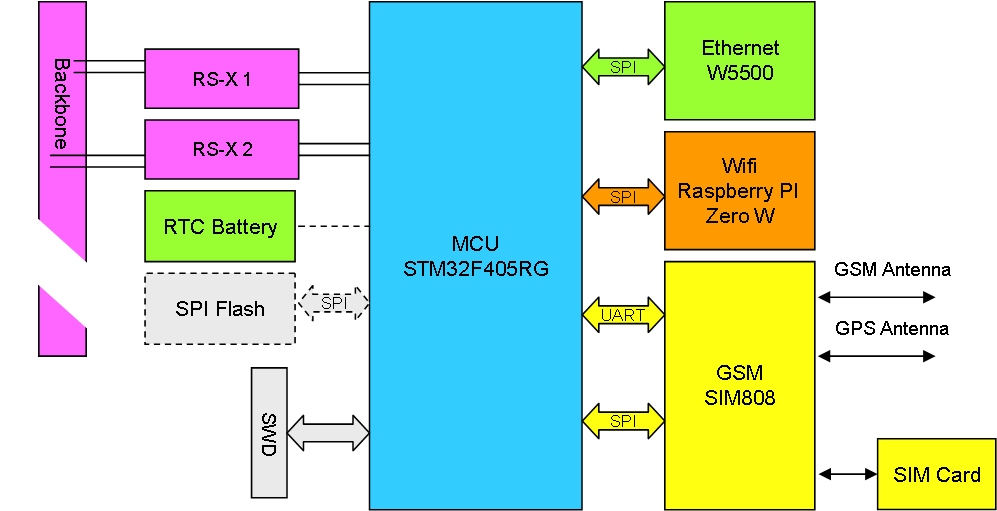

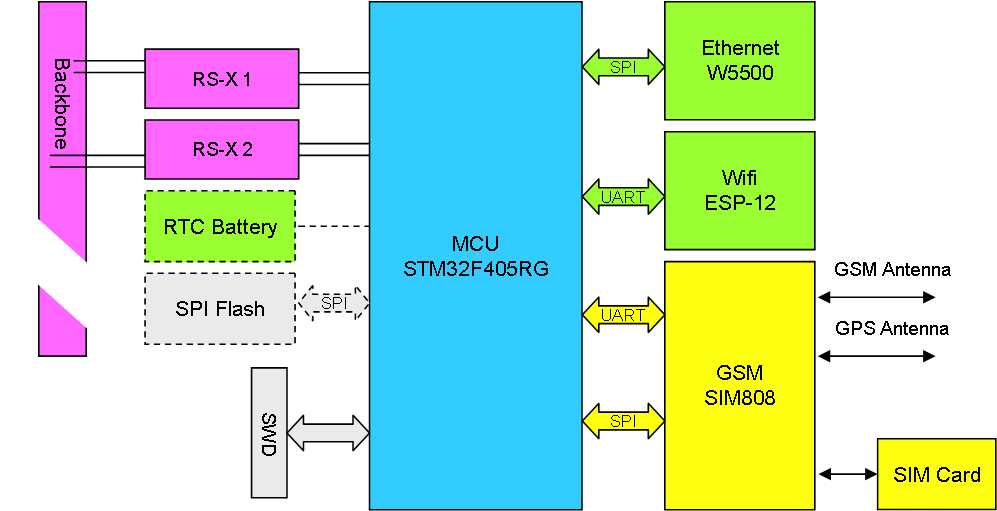

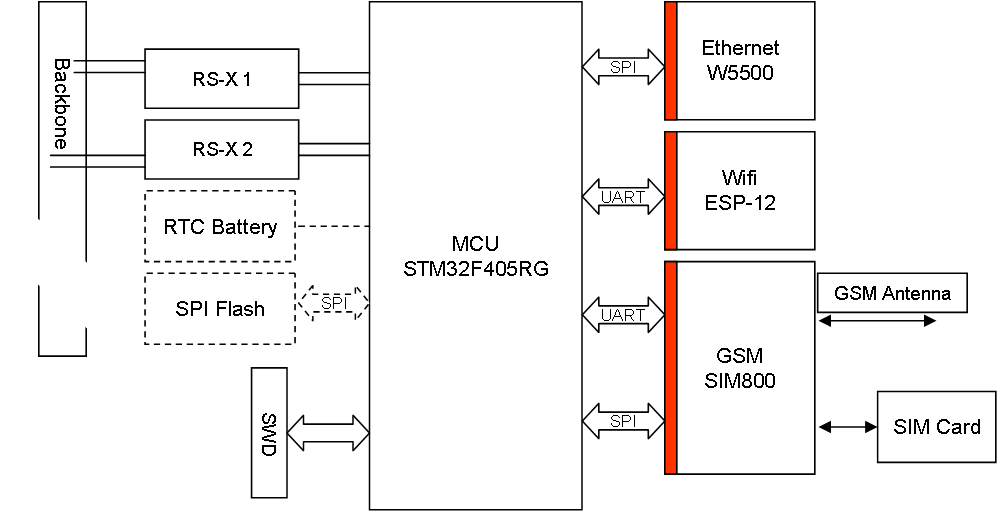

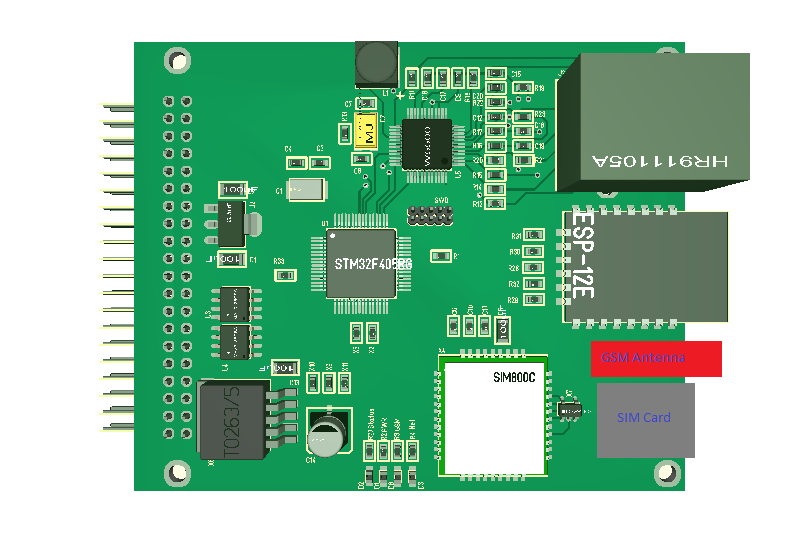

Meet my new Ethernet/GPRS module. I am not finished routing the PCB and lack some 3D packages, but you get the idea. This 3D modeling tool is a bit ruff in the edges anyway, but it serves it purpose. Also, I still have a few loose ends here – so work in progress…

This 3D show a small button battery holder for RTC, but the SIM808 has a build in battery charger for a single 3.7V LIPO so considering if I can use that or add my own – I consider attaching a larger 3.7V LIPO battery on the back side to drive both MCU and SIM808, but I also need on/off for RPI if I do that. Basically the 5V from the back plane would charge the battery. For RTC I could use my old trick an insert a small supercap.

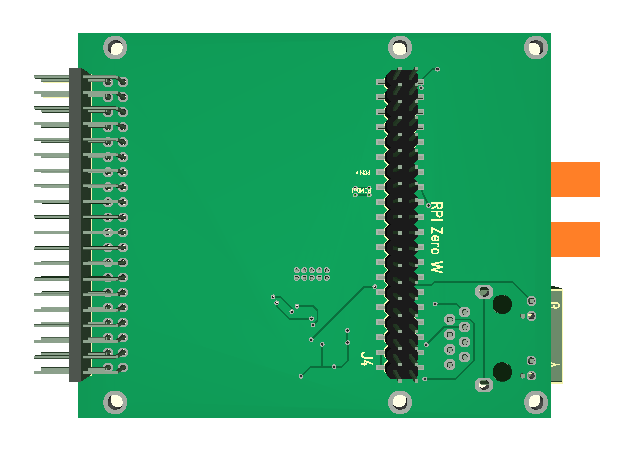

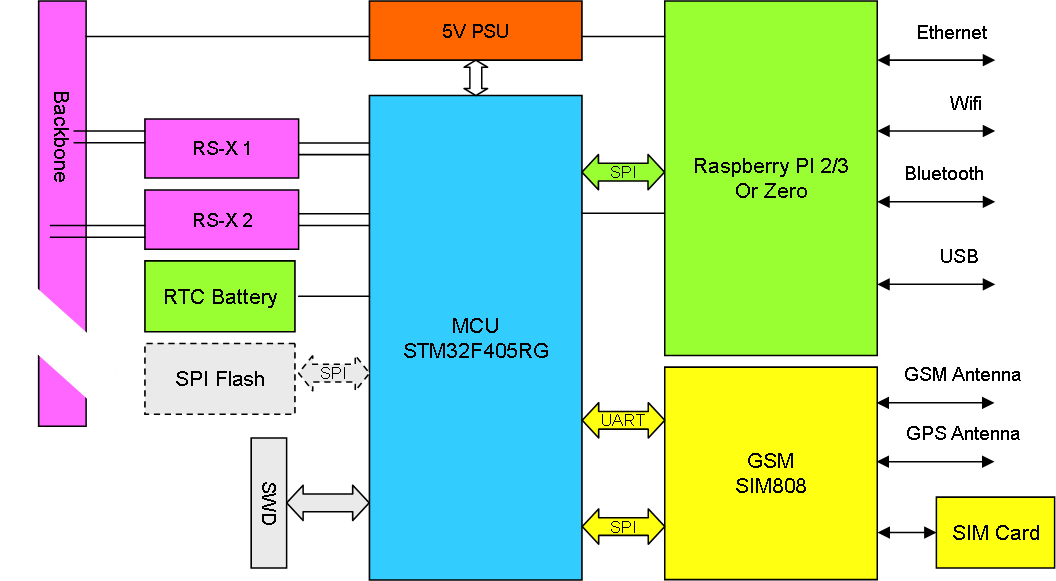

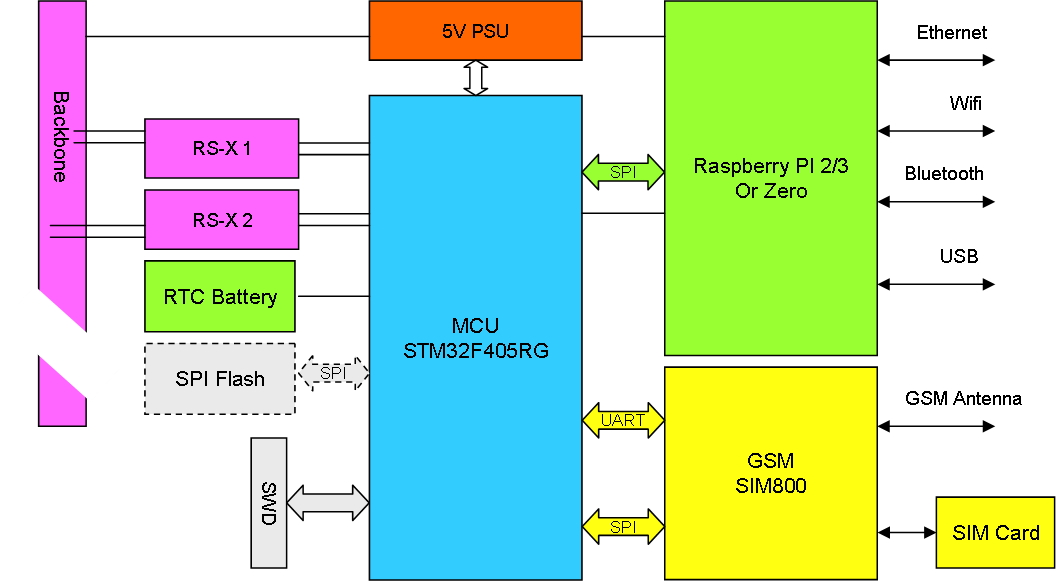

This shows the backside with the connector and mounting holes for a Raspberry PI Zero Wireless add-on. This add’s secure wifo + bluetooth as well as a very capable Linux server. HDMI & USB will be at front. Needless to say this can also connect a full Raspberry PI 3 using a 40 pin cable.

I am considering using the Space left of the Raspberry PI module for a LIPO battery as mentioned earlier.

As for the All-In-One Home Central I could just make a 1-2 card dedicated backbone with a 5-6V adapter and this would serve the purpose…

At precent I see no purpose in makeing a separate GSM, Ethernet or RPI module as indicated earlier – this combi does the job very well. Don’t be surpriced if you see the Zero W popping up as an option on more modules.

Loose ends/notes:

- Battery charger/LIPO- I have little Insight into the build-in charger, so consider finding a different solution that also can be used on other Boards. Need digital on/off for RPI.

- Antenna – not sure about the quality of my PCB shielding so considering using these micro taps and allow people to supply a shielded cable directly rather than adding 3-4cm of PCB lanes.

- USB. I have space to output pins, but not for a connector.

- Mic/Speaker – I have space to output pins to a header.

- Bluetooth antenna on SIM808. Should try to add a micro antenna connector – yet another component I need package for. Not sure I ever need this, but I do have space for it, so why not.

- GPS antenna crossing RPI header. Should ground pin 15 (GPIO22) & 16 (GPIO23) on the RPI header to create a continious ground plane under the antenna signal.

- GSM Antenna is close to the SIM card. Possible to just move the card holder to the otherside with strong ground plane support to minimize effect. Either that or moving the SIM card holder to the middle of the card in which case it will be a pane to insert card. Not sure if this is a big issue.

- RTC oscillator must be added, but little space here. We can use the HSE/8, but not sure how accurate that option is. Possible we can ignore the RTC clock on STM32 as we also have one on SIM808.

- Consider if we need to add TVS on 4V. The Reference recommend this due to 2A on/off surge. This should not be any issue with a LIPO connected here. But, we should have space for this TVS so could just add it on PCB.

- Some other LEDS from SIM808 – not sure if they add any value.

- Top/Bottom edges need a clean up. Considering using a sliding holder and avoid screws in which case we need 1-2 mm clearing on top/bottom for a track.

- Need to increase aura around drill holes and avoid these being ground. This is a mistake I have done repeatedly as I by old habit ground through mounting holes.

- Need to adjust mounting holes for Raspberry PI Zero accurate.