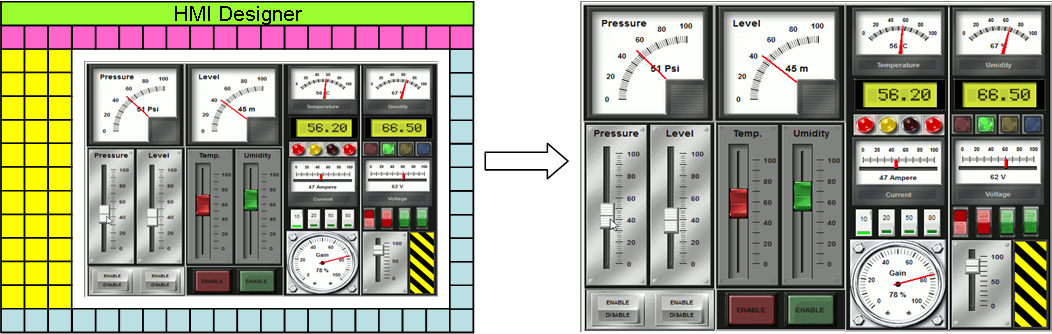

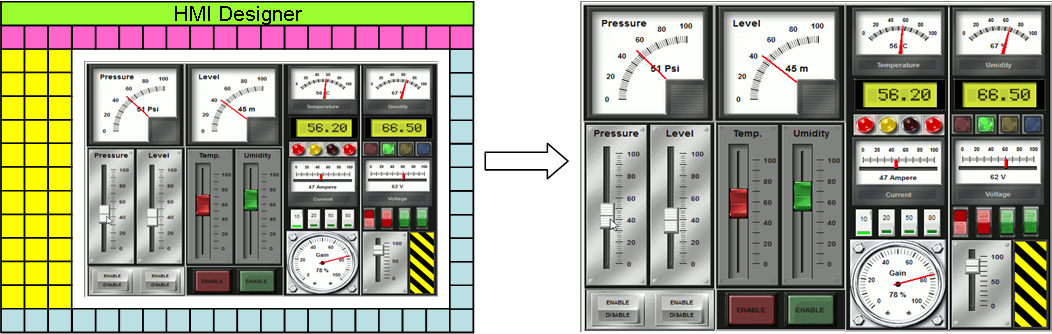

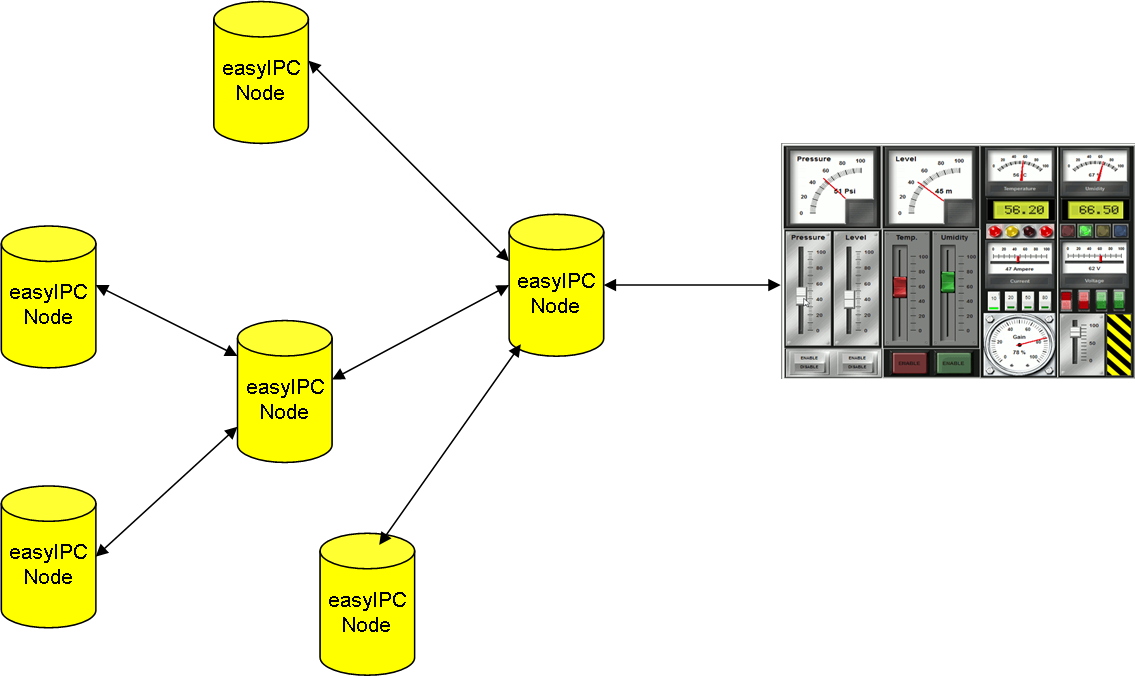

One of the applications I want to create is a “HMI Designer”. This is technically very easy as I have done similar applications before. What I will do is to create a graphical application that can design square objects on a form. Each object will have a name that we can use for IO through a serial line. To make the designer a bit more WYSIWYG we animate the objects as if they where “furniture” like Text Edit, Graphic Plot, Grid, Button etc. Each object will have a list of properties that are set/get design and run-time. The result is stored as an XML file and executed by a “HMI Browser”, a special application that download the XML and interact with the system.

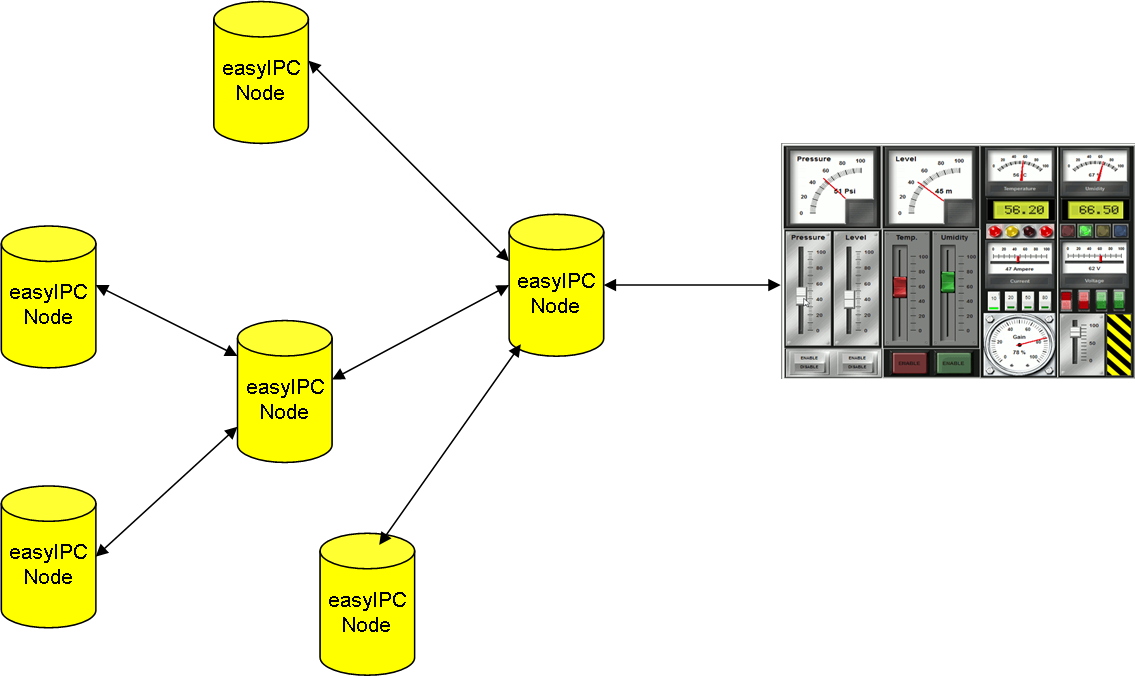

This way we can design config HMI’s stored in the embedded devices as XML files and we only need to re-create the HMI Browser to support HMI on Windows, Linux, OSX, Android etc. The concept is not so unlike a Web Browser with the exception that the server here can be small embedded system in a closed loop. Nextion are selling displays build on a similar concept, so in time we can do our own embedded graphics displays as well. I do however want to do tings a bit different from Nextion.

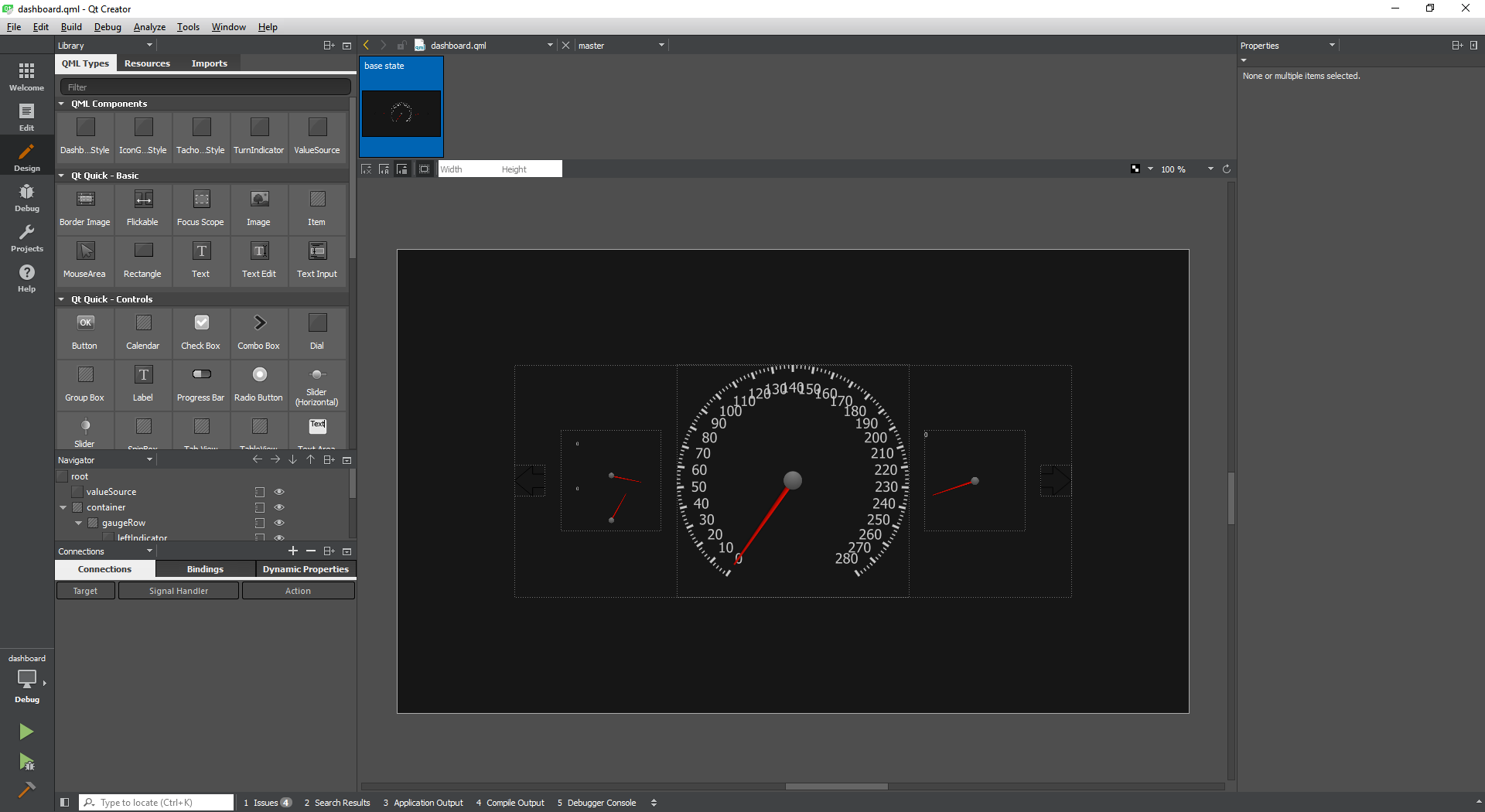

One of the differences is usage of Plain as “scripting” language and interfacing using easyIPC and RSX as well as Ethernet/Wifi. The other difference is that I want a significantly larger object library and take advantage of GPU’s on Raspberry PI etc. I also want this to be a portable software package, not locked to proprietary hardware.

The most important difference is however system thinking. I want HMI Designer & HMI Browser to be building blocks in the CASE (Computer Aided Software Engineering) Tool I want to create on top of Plain. For now we will use Plain and the HMI Designer, but I do plan a fully graphical programming concept later.

As mentioned before with my Plain blogs I want to evolve the way we do software based system development. The network I build here have plenty of fun for C programmers and electronic hobbyists, but we need to create infrastructure and tools enabling this for non-specialists.