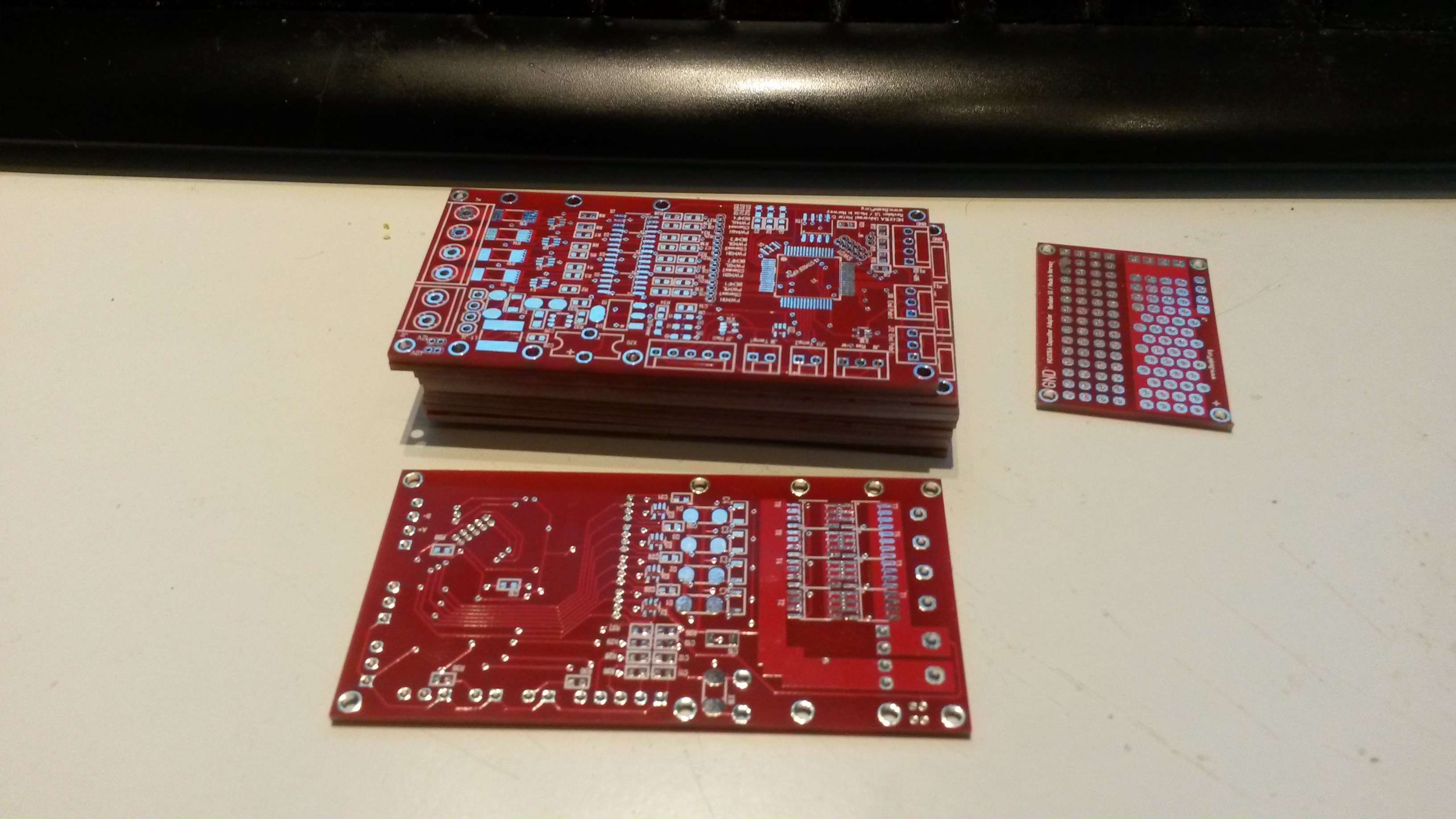

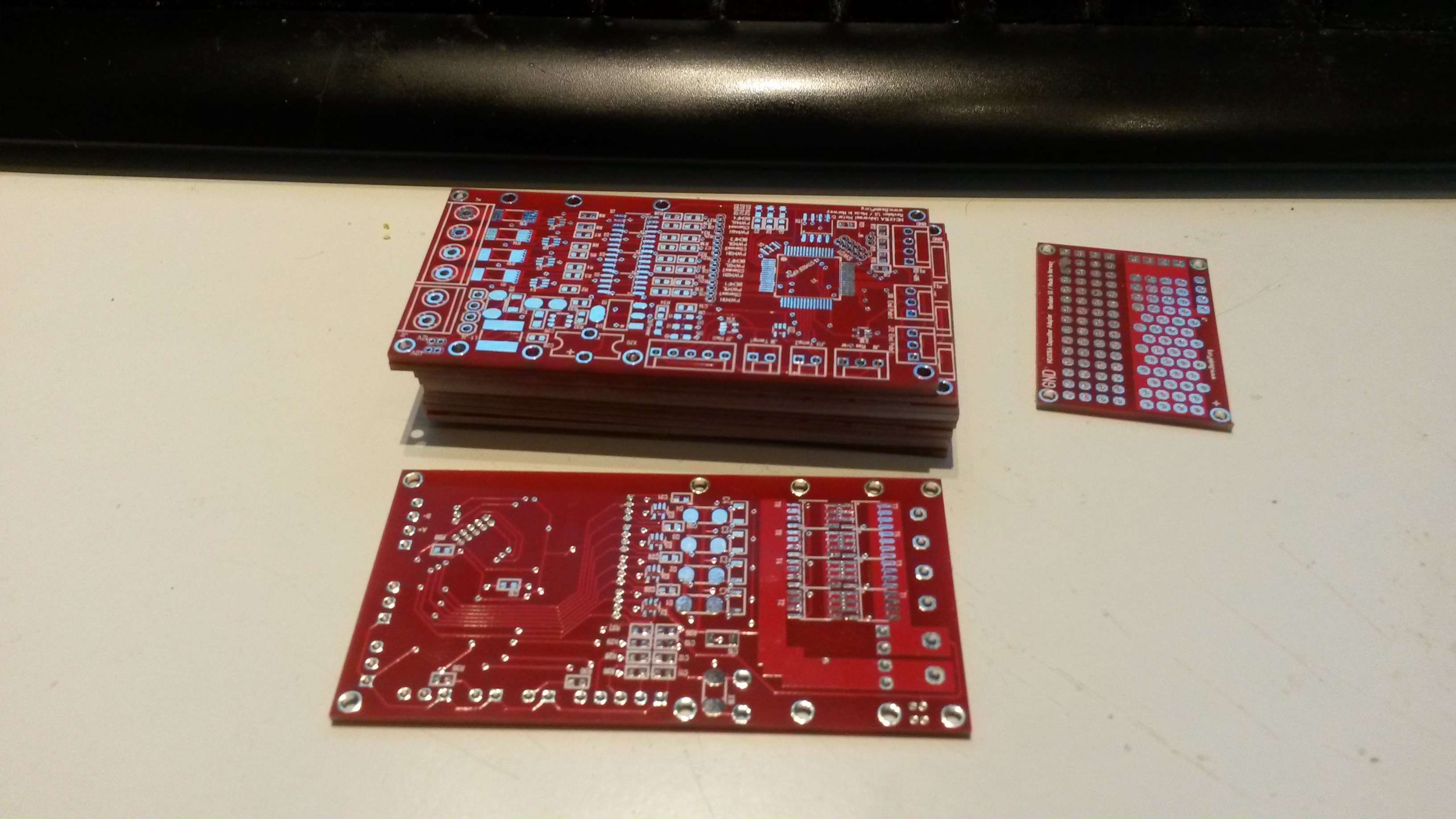

I have a few electronic designs that annoy me simply because I lack time to work on them. The reason is simply to much happening in RL with projects (have to pay the bills) + focus on Software. This one is the worst. It is actually one of my most advanced designs and a very capable Actuator Control System.

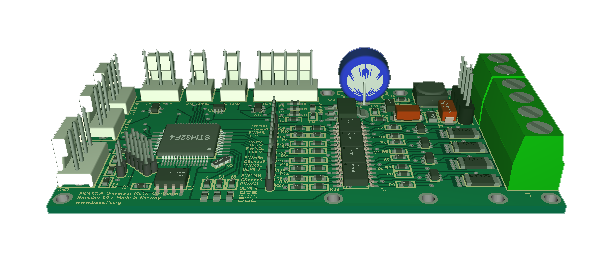

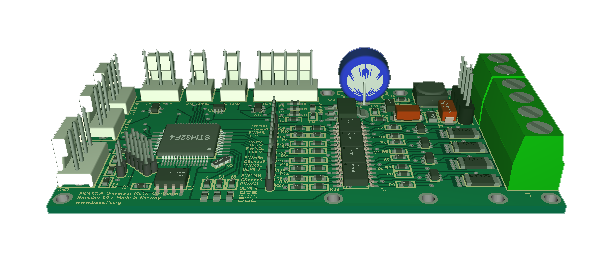

I started this partly because I wanted to make my own 3-phase motor controller. But, as I did the design I also added a 4th Half-Bridge, Hall Sensors, Temperature Sensors, End point Sensors, Resolver input as well as the RS-X port. It is much better 3-phase motor controllers than this around, but that’s the point – this is not a motor controller it is a scalable Actuator Control System.

I

I blogged a lot about MicroPLC/Home Automation lately, and this design fit’s right into this scheme. We can’t use long wires with actuators involved as they need to be close to the objects they control (high currents). A centralized PLC design is not optional in a home that actually need distributed unit’s like this.

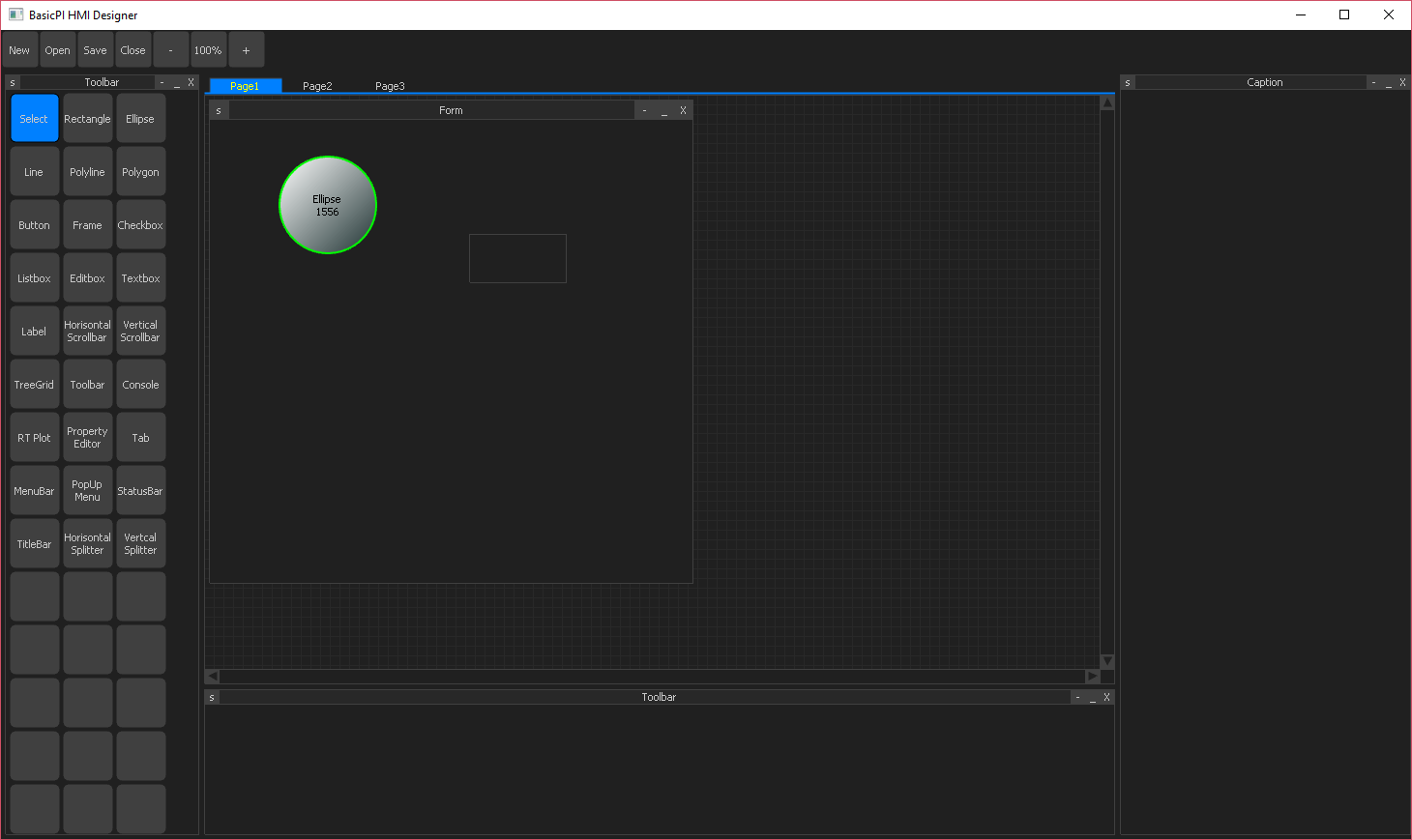

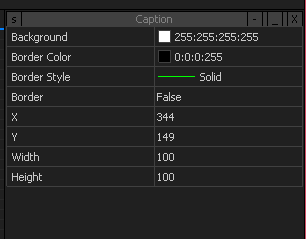

I will get down to it, but for now I want to focus on getting the HMI running. One of the first projects will be test applications for these devices.

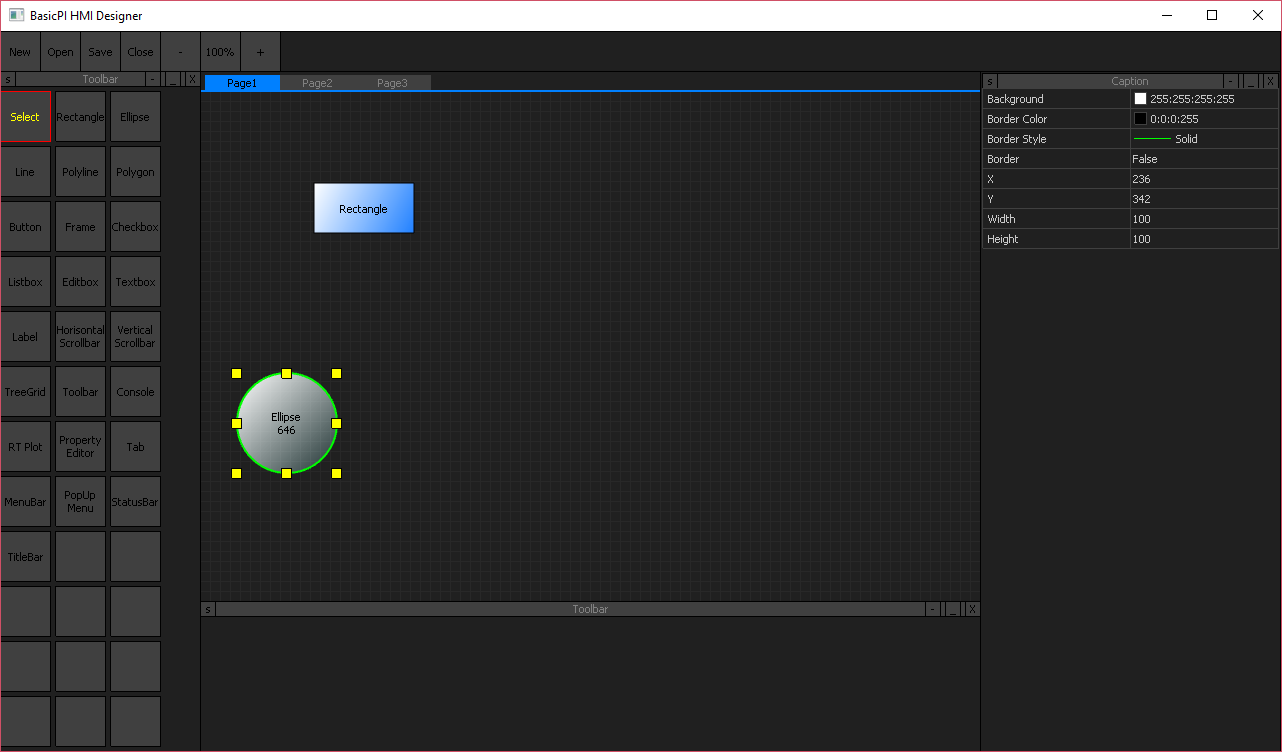

The concept I will use is that the HMI Browser contact this device and upload the HMI. So all you install on the desktop, phone or tablet is a HMI Browser. This is similar to things you know from classic Web Browsers and HTML5, but the main difference is that we operate on a closed, industrial network consisting of a combination of technologies.

One aspect of easyIPC that I have not mentioned is that you have a set of HMI & devices that actually are a closed, industrial loop. It is not connected or available to internet or the outside world unless you want it to. Neither will you be able to connect any phone or tablet if it is on Wifi – the devices will need to be enabled from inside (white listed).