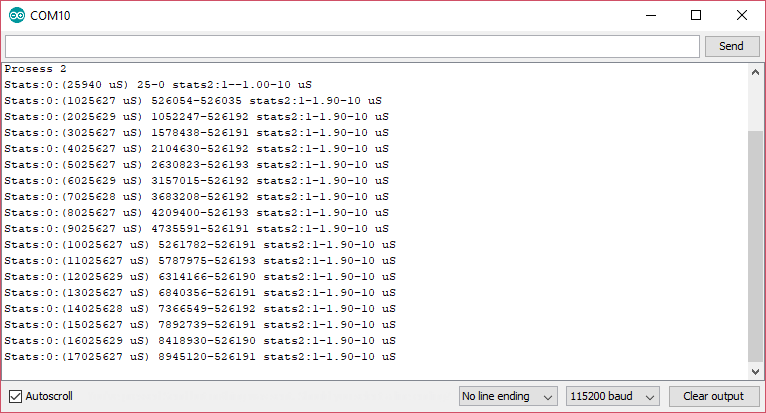

I recently bought a DPS5005 which is a 5A variant of the larger 20A DSP5020 I wrote about earlier. This module can deliver 0-50V/0-5A and have all the electronics inside the display module. Testing of this proves to be very good and it’s a good match for the 36V/5A driver module. As it all also fit well within a low-cost metal cabin I decided to build a dual Lab PSU.

The picture above is the HMI module. The larger DPS5020 have a separate regulator board while the smaller DPS5005 have the regulator board inside this module which makes it very size optional. Both modules are with USB. Basically I just wanted the RX/TX and Modbus in place so I can expland the Lab PSU later.

One of the things I really like with this HMI is that turning the knob by accident changes nothing. You actually have to press A or V first. You also get to adjust out power before setting it out. In fact the HMI does not look like much, but it is very impressive and clever design.

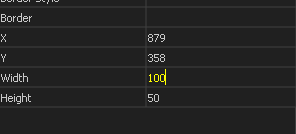

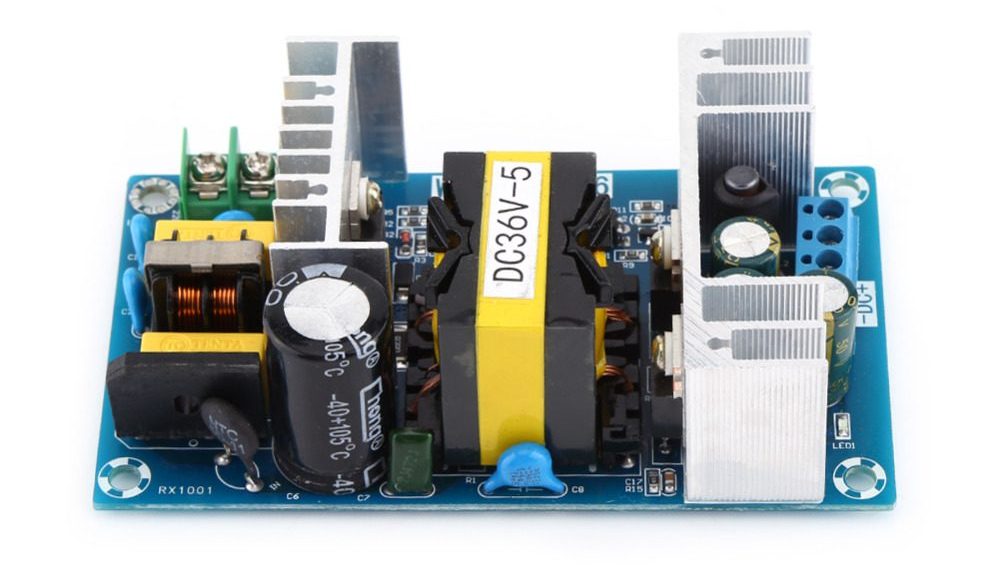

This picture show the 230VAC to 36V/5A driver module available for ca 10.- USD. DPS5005 can deliver 50V out, but as this module is limited to 36V it delivers only 35V out. This is however more than sufficient for basic needs.

This is the 17.- USD box that I use. The plates are steel, so it’s a bit of a job drilling holes etc. But, it is sufficient room for fuses and mains connection, 2 x driver modules, 2 x displays and 2 x PSU connectors. Making the holes went a bit messy. Basically the plate ended up bent around my drill, so I I had to hammer it back out and decided to change color. Was not too found of the blue in the first place.

This shows the all-in-one mains connector, fuse and on/off switch. The only drawback is that I end up with the on/off switch on the back, but I can live with that.

This shows the all-in-one mains connector, fuse and on/off switch. The only drawback is that I end up with the on/off switch on the back, but I can live with that.

The last component is this female banaa plugs in front, one for each PSU. The table below show the BOM and the ca total cost of the PSU. All these parts are avaiable on www.aliexpress.com

| 2 |

DPS5005 |

32.- USD |

64.- USD |

| 2 |

Drivers 36V/5A |

12.- USD |

24.- USD |

| 2 |

Banana connectors |

2.- USD |

4.- USD |

| 1 |

Mains connector |

4.- USD |

4.- USD |

| 1 |

Cabinet |

18.- USD |

18.- USD |

| Total |

114.- USD |

A single PSU 0-30V/0-5A is usually around 100.- USD with P&P. A dual PSU (cheap) would be ca 150.- USD++. This is a programmable, dual PSU. It will cost me anoth 50.- USD to add the ESP32 and HMI later, but once that is done you have a PSU that normally cost several times more.