Update : 13 of 50 MOSFET’s might be ok after testing!

I purchased 50 x IRF7862 MOSFET’s from Asia through AliExpress and while I usually am happy with what I buy here it happens that I get screwed by non-honest sellers. What some of them do is to pick rejected chips from the factory and sell them. These MOSFET’s arrived in a plastic bag, not in original packing so I should have rejected them due to that alone, but I was obviously not on my watch back in 2016.

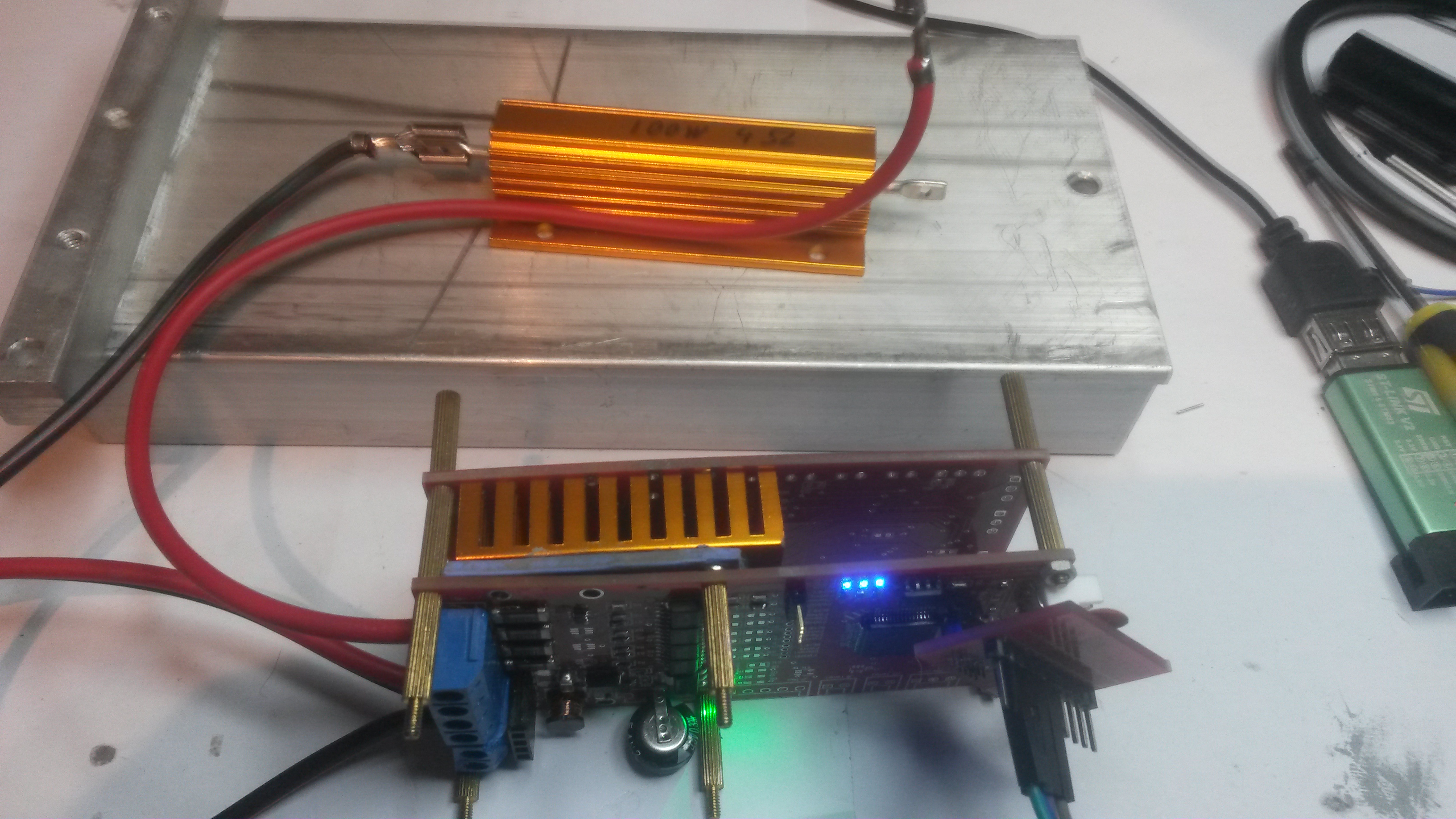

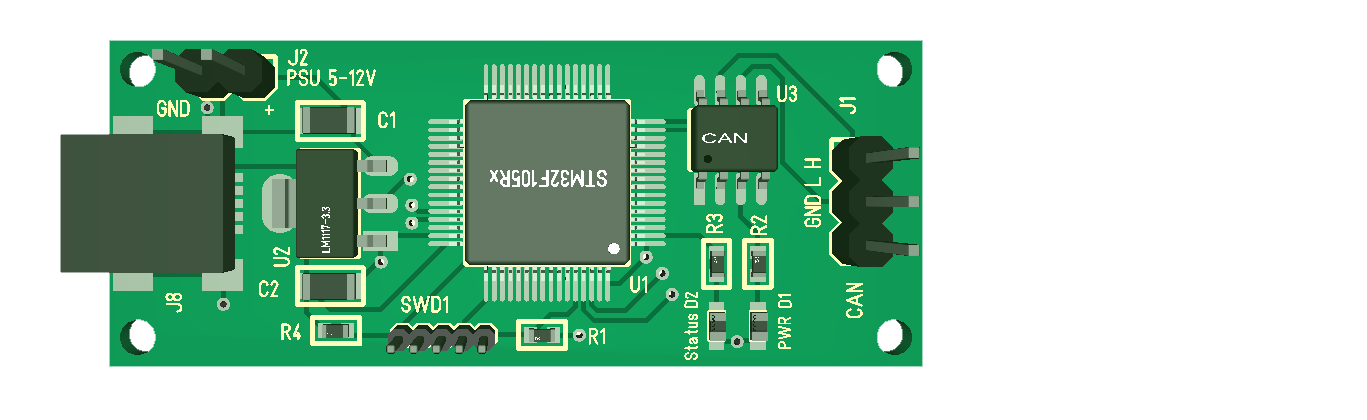

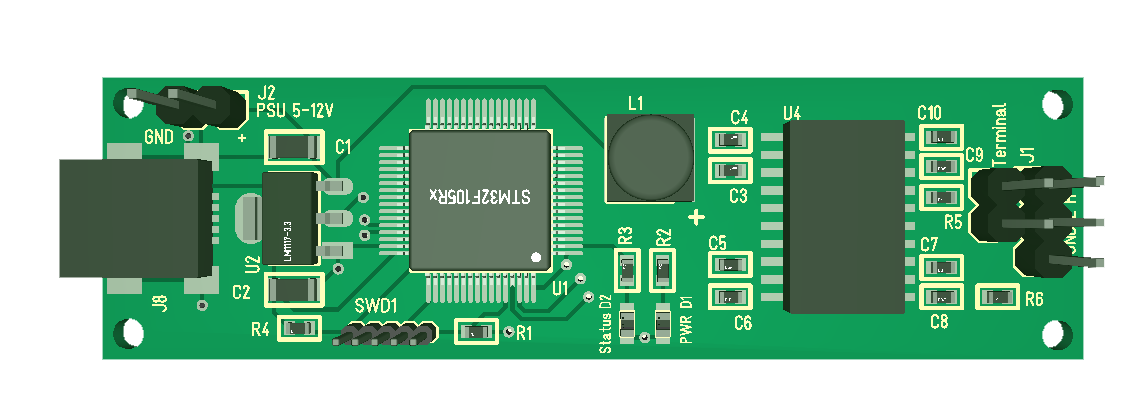

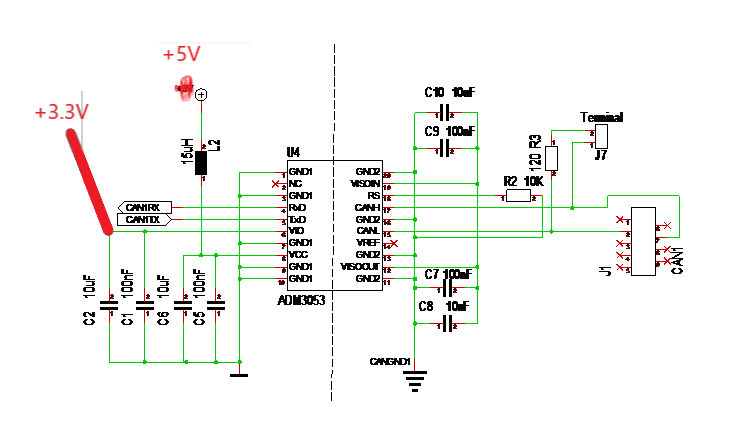

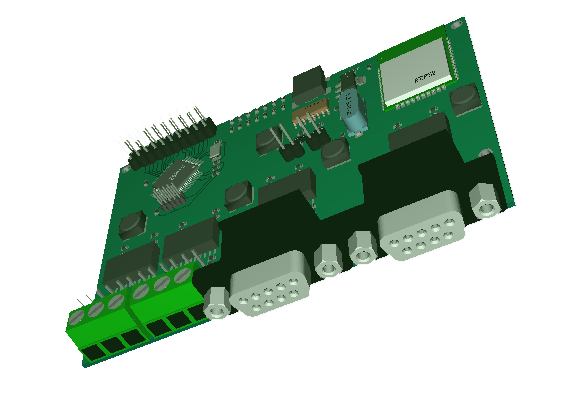

These was for my motor driver and are supposed to have 3.3mOhm internal resistance as well as a very fast switch time. I was therefore a bit surprised that they generated so much heat as they did and that so many of them was destroyed so fast. After I destroyed my test channel yesterday I soldered on a new one and realized it was non-working as well. I tested the lot manually and had to reject 6 of them. Soldering on 2 new ones I still discovered that they did not work. Scoping the gate I even see they distort the gate signal, so 2 new ones and gate signals are ok, but output (no load) is crap.

This lot was bought back in November 2016 and costed 16.45 USD (0,329 USD each). Well, this is what you must expect from time to time buying samples from AliExpress. I believe this is the 2nd time I had bad luck like this. The alternative to buy all components from distributors would be far to expensive for a hobbyist scheme.

What I will do next is to test manually and see if I can find a few that hold ca spec. This is easy as you just use the PSU, connect on each end with 10V over the MOSFET, put the current limit to < 1A and bring the gate to 10V. This will bring the PSU down so I will not get 3.3mOhm as Voltage will be to low, but it will indicate if they work at all.

I must admit I thought these MOSFET’s snapped a bit fast, so I had actually planned to replace them With IRFH5300, but I need a New PCB layout for these. IRFH5300 is rated to 30A. I don’t expect to get 30A out of this design, but they have a much lover resistance and I should get 15A out with far less heat. Luckily the IRFH5300 was from a profiled seller and arrived in original package.

Returning to IRF7862 – what I will buy 20x from different sellers and pick a profiled seller this time. I also see that price range is huge + a good indication that something is wrong is if you don’t receive chips in original package – these came in a plastic bag! Prices range from 0.28 each to 0.90 each. I picked IRF7862 due to it’s low cost, but if I have to pay 0.90 each I can as well use IRFE5300.