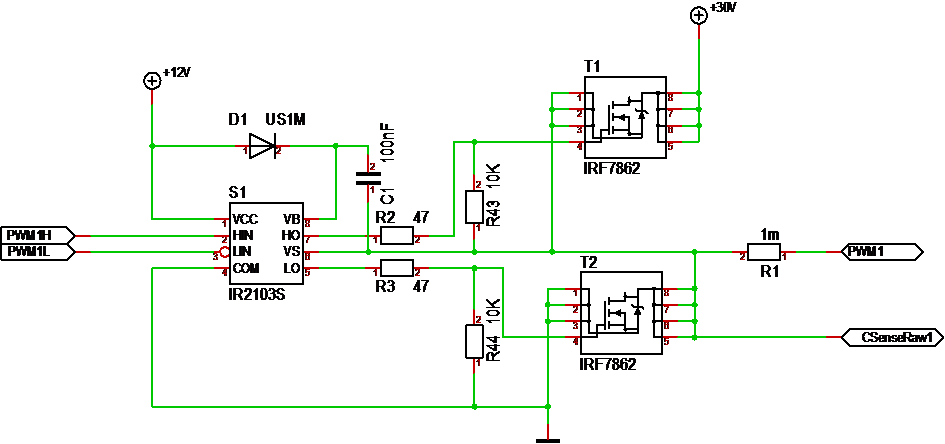

This shows my new driver circuit. I added R43 and R44 as weal pulldown’s to avoid that the MOSFET start leading by accident at power up. If I get space limitations I will rather remove R1 and R2. This will make it safer to put power on a Motor Controller in case the Gate Driver is disconnected or broken.

MC4X24V15A Motor Controller Upgrade

I still want to test more with rev 1.0 of MC4X24V15A, but I am also planning an upgrade. I initially drew a rev 1.1 using 78M12, but I will replace LMR14206 with TPS54x60 and AMS1117 with SPX3819. That will increase range to 60V which basically means 48V. I do have the challenge that I also want 12V and I need 12V on the Gate Drivers. The only solution I know of is by bypassing the DC/DC if input voltage is below 14V.

The supercap stays, that part of the design was really succesfully, but I need to consider if I need 5V as well for the Hall Sensors etc. In which case I need 4 voltages on the controller.

I will change to the new SWD to save some space + this should be better in this case as it won’t be in the way.

I will also change the connectors to JST Micro as I see little purpose in the larger ones.

I would like to find smaller diodes for the Gate Driver chargers.

I also consider dropping that cap add-on and get the caps directly on the board. Use 1000uF 16/35V in series etc.

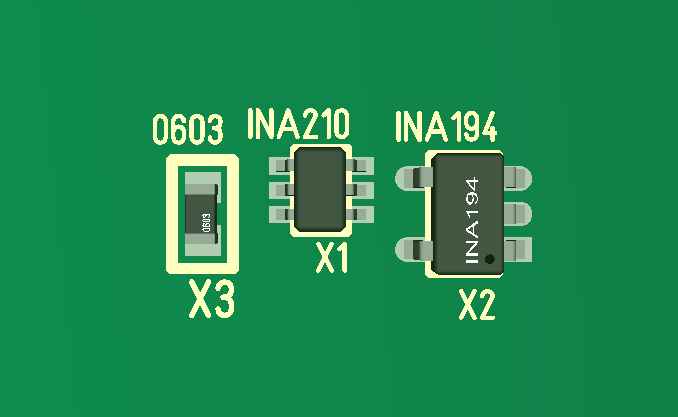

INA210 will be replaced with INA194.

I need to test that Hall Sensor circuit and consider changing it.

Temp1 and Temp2 needs to be changed.

Resolver port can be removed.

And then comes the question about the MOSFET’s. IRF7862 is great, but some of the new ones are just in a different scale. 3.3mOhm versus 0.65mOhm is a huge difference as the later will allow much, much higher currents. But, if I make the footprint for SOP Advance a SOP-8 will also fit onto that. The only difference is the PAD on SOP Advance. I can even stick SOP Advance on SOP-8 with some care – I just do not get the advantage of the PAD’s heat dissipation. But, I do need to remove a place-through underneath the IRF7862. With this I can interchange MOSFET’s. New product name will be MC4X60V15A. I don’t plan on changing the 15A limit. MOSFET’s will take far more, but PCB lanes will start burning.

Returning a bit to MC3P60V50A I realize that I have done a few mistakes. Some of the smaller capacitors needs to be 60V+ and I need to put the main capacitor somewhere. All in all I might have to use a few more mm in width which is fine.

I am still waiting on PCB’s for MC3X3A. As for the micro one using DRV10983 I am actually considering ditching that one. It run’s the motor, but I am not impressed. After a while it heats up and misbehave. I tried a L293 just to compare and was more impressed by how easy it was to use this to run the same 3-phase motor. I liked DRV10983 over DRV8313, but – well – I will code it’s I2C interface and see what I can achieve.

Insane MOSFET’s

Searching on Arrow’s pages I found 3 MOSFET’s in SOP Advance package that have insane ratings.

- 2. 40V 246A Rds=1mOhm 1.2 USD

- 3 45V 280A Rds=0.8mOhm 1.4 USD

- 3. 30V 280A Rds=0.65mOhm 1.3 USD

Actual limit is more like 150A with a pulse drain of 500A in accordance to datasheet. But, look at the RDS on that 30V MOSFET – 0.65mOhm. With a power dissipation of ca 1W as a hand-rule that means almost 40A without a heat-sink if my calculations are correct. Lets try them out!

I ordered 10 of these to test because they are very attractive for a 12V/24V design where you benefit from higher currents. I have no intention of even trying their datasheet limit as I am more interested in the range 15-50A which should be well within their capabilities.

FedEx has been nice and responsive and they basically told me how to avoid getting slammed with extra toll fee’s, so they are forgiven

FedEx “free-fee”

I have always avoided using FedEx or similar services as I import Electronics due to the cost of their services. But, as I decided to buy 4 packages from Arrow in US and found that they offered “free” P&P using FedEx – why not?

I am really impressed with Arrow and some of the deals they offer as they out-compete Asian distributors head to head on price. I assume this is strategy from Arrow as they want to be supportive in prototyping and be chosen as distributor then the volume hits in.

This should also be a golden opportunity for FedEx and with all respect – FedEx was quick to deliver even if they never found my house

Arrow is (according to FedEx) not stating the P&P correctly on the package, and that causes FedEx to slam the package with a P&P they have to calculate + a fee for doing this job. The result is that for a package costing 29.- USD I end up paying ca 24.- USD extra for a so-called “free” P&P. A package costing 29.- USD would be toll free, while a package costing 41.- USD get slammed with MVA according to Norwegian import rules.

I am told I can get Arrow to document this correctly and get my money back – in 6 months time – but, I have no intention of continue using FedEx and having to waste time and cost on this if I can avoid it! Sadly this will also limit the usage of Arrow. I will not stop using them, but “as is” I will have to calculate a 100% FedEx “free-fee”.

As mentioned before – a waste majority of Asian import is absolutely ok for proto-typing. And I can deal with the few exceptions and waiting a few weeks. What I can not afford is to be slammed with 100% stupidity every time I buy a small package as that would force me to stop this blog and my hobby.

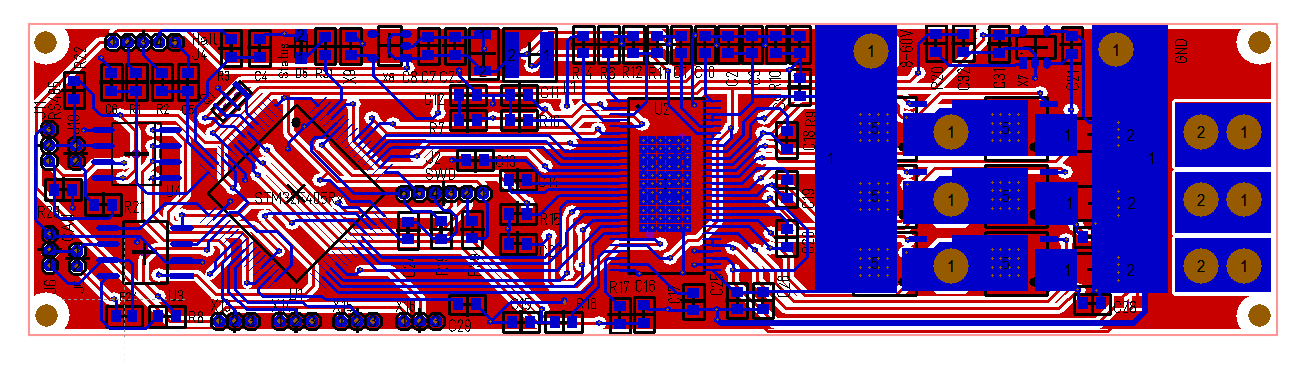

60V/50A Motor Controller PCB

This one was not as hard to route as I expected. I had to do a few compromises and I need to look things over. Ground plane include a few lines that I want separate etc + I need to ensure that all ground planes are connected. But, this looks good. A bit to dence and I really could have needed 4-6 layers here for analogue signal quality.

- Size 100x25mm

- 8-60V / 50A capacity

- STM32F405RG or STM32F105RB etc

- RS485

- CAN

- Hall Sensors or Encoder port

- 3 x Current Sensors

- 4 x IO ports (3 analogue capable)

- DRV8301 based

- 160A MOSFET’s

- Components on top-side only.

Returning to my 24V/15A design it is actually the same SOP-8 sized MOSFET’s, so as soon as I have tested the 60V DC/DC and current sensors I will upgrade that as well. I need to decide if I want to leave it at 24V or upgrade to 60V or increase current capacity.

Looking at MC3P60V50A above you can also see that close to 33% of the board is DRV8301 (Gate Driver). This is 2 cm longer than MC4X24V15A, but more narrow since it has 1 less channel and did not need the separate DC/DC. Components on top-side only is a big win.

Printing this one out on a printer is actually scary – it is much smaller and denser than I realized, but this will be fun to play With.

Fedex Norway slam customers

I purchased 4 packages from Arrow in US (MOSFET’s) and I was surpriced that P&P was included free – and yes it is. But, Arrow uses Fedex that add a fictive P&P as this is declared to Norwegian customs and this made the value look like it was above the free import limit – which it is not! This basically allow them to charge me 12.- USD in handling fees on top of 12.- USD in MVA. So a package that costed 29.- USD suddenly “cost” ca 53.- USD. That is almost 100% import duty on packages from US in this case. These packages are actually free (no MVA) below 40ich USD, so this makes a big difference.

I have complained to Fedex and Arrow. I will not stop using Arrow, but this extra cost will need to be calculated in. Arrow is an innocent victim of a very bad Fedex practice here! Fedex are actually obligated to find out what the actually P&P is and inform customs, something Arrow should have stated in the invoice.

I will complain about the extra invoices. I feel sorry for Arrow that actually have made a very competetive deal and get their business slammed by a bad Fedex Norway practise.

MC3P60V50A – 3KW Motor Controller

This will be work in progress for another week at least. I have routed the right side of DRV8301, but I have the left side + MCU left. I initially started with a STM32F303CB, but decided to move up to a STM32F405RG. Current size is ca 100mm x 25mm and components only on top side. I have received the 60V/160A MOSFET’s I plan to use.

This is a dedicated 3-Phase controller. I have so far added JST connectors for SWD, CAN, RS485 and 6 sensor inputs. I will add bias and jumpers for RS485 top-left + I would like to add a USB connector, but I probably need to sacrify CAN or RS485 to do that.

Compared to MC4X24V15A this is 20 mm longer and 15mm thinner design with components on the top side only – but, let me finish routing before I brag to much – I do however think that worst case here is another 5mm in thickness due to density on left side – lets see.

I will solder up a new MC4X24V15A to complete testing and start writing actual code. I have received the MOSFET’s. The old board is stil working, but reduced to 12V due to some destructed lanes that proved difficult to repair. But, that is ok for algorithm work on lower effects.

Size of things

This show 3 components on a 3D model. The one to left is a 0603 package, and if you have any idea of how small that is then you also see the size of INA210 in the middle. INA194 is SO-23/5 which is “easy”. I consider 0603 easy as well, but 6 pins on that INA210 was a bit on the edge.

I have never tried a 0402 component and based on my experience with 0603 I don’t think I want to either – not with manual assembly.

L293 Arduino Shield Limitation

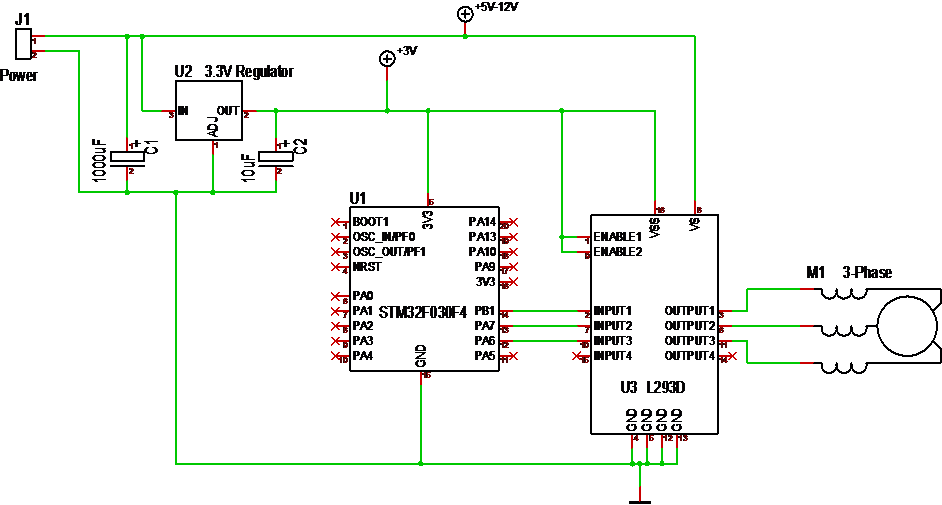

L293 – 3 Phase Arduino Motor Controller

This little circuit is a 5-36V 3-Phase motor driver. In this case I use 3 channels of a classic L293D to output to a small 3-phase motor and run it using a Trapzoidal motor algorithm. I am running L293 on 3.3V, but it will work better on 5V and an Arduino is better for this experiment. MCU’s like 8-bit AVR and PIC have been used for 3-phase controllers for years, and as this example will demonstrate you don’t need much to spin a motor using Trapsoidal or Sinusoidal algorithm’s.

The concept of Trapzoidal is that you pulse each phase in sequence A->B->C and repeat it to turn the motor in one direction. To reverse you do C->B->A. How fast you spin is now your speed as you drive the coils directly by pulsing. You will discover that if you go to fast the motor will not start and if you go to slow t will bump in steps.

To improve the algorithm we take advantage of the 3 coild. Using A create one position, using A+B creates a 2nd and using B creates a 3rd. So we now output PWM to A->A+B->B->B+C->C->C+A and repeat it. You now have the 6 steps of a Trapzoidal algorithm.

if(forward) { Set3Phase(1,1,0,sOn,sOff,speed); Set3Phase(1,0,0,sOn,sOff,speed); Set3Phase(1,0,1,sOn,sOff,speed); Set3Phase(0,0,1,sOn,sOff,speed); Set3Phase(0,1,1,sOn,sOff,speed); Set3Phase(0,1,0,sOn,sOff,speed); } else { Set3Phase(0,1,0,sOn,sOff,speed); Set3Phase(0,1,1,sOn,sOff,speed); Set3Phase(0,0,1,sOn,sOff,speed); Set3Phase(1,0,1,sOn,sOff,speed); Set3Phase(1,0,0,sOn,sOff,speed); Set3Phase(1,1,0,sOn,sOff,speed); }

If you drive the motor directly you need to send a PWM with sufficient length & torque to move the rotor. This will vary with input voltage, but start at 5V with 50% PWM duty. I had to use 100% at 5V and 30% at 12V. Once the motor is started you can accelerate it up into speeds.

The drawback with this algorithm is that it has no knowledge of rotor position so the vector we output might be wrong. In most cases it will need ca 1 turn to sync with the rotor.

Trapzoidal algorithm is not used these days because you can as well use the Sinusoidal algorithm as minimum. But, a simple trapzoidal algorithm can be implemented in logic without a MCU involved.

The Sinusoidal version is based on a Sinus curve. While we on Trapsoidal have 6 steps we will on sinusoidal vary PWM duty on A,B and C to create as as many steps as we want.

Keep in mind that a coil act as a filter, so with 5V and 50% duty I am actually outputting 2.5V. By changing PWM duty I can create several more steps to make the motor move smoother. This require a bit more math, but most MCU’s can manage a pre-calculated lookup table etc.

The remaining question is however – where is the rotor? To know this we need to add a sensor. In fact we have 4 different ones that can be used for measuring speed and rotor position.

- BEMF. As we output voltage on 2 coils we can measure the feedback on the 3rd. I have never tried this, but the feedback should tell us something about position.

- Current Sensor means you add a low- or high-side current sensor on each phase and you can use them to calculate rotor position.

- Hall Sensor will give a position signature based on magnetic fields.

- Resolver will give you position.

Knowing the position you can use this to look-up the next entry in Trapsoidal or Sinusoidal algorithm. But, you could also do more advanced math to calculate a perfect 90 Degree vector – this is the FOC algorithm that requires a M3 or faster to be possible.

A lot of my articles dig into the more complex sides of running a 3-phase motor and might give the impression that this is more difficult than it is. So, I advice you to get an Arduino (or whatever), connect a L293 and start spinning a small 5-12V 3-phase motor to see how easy this actually is.