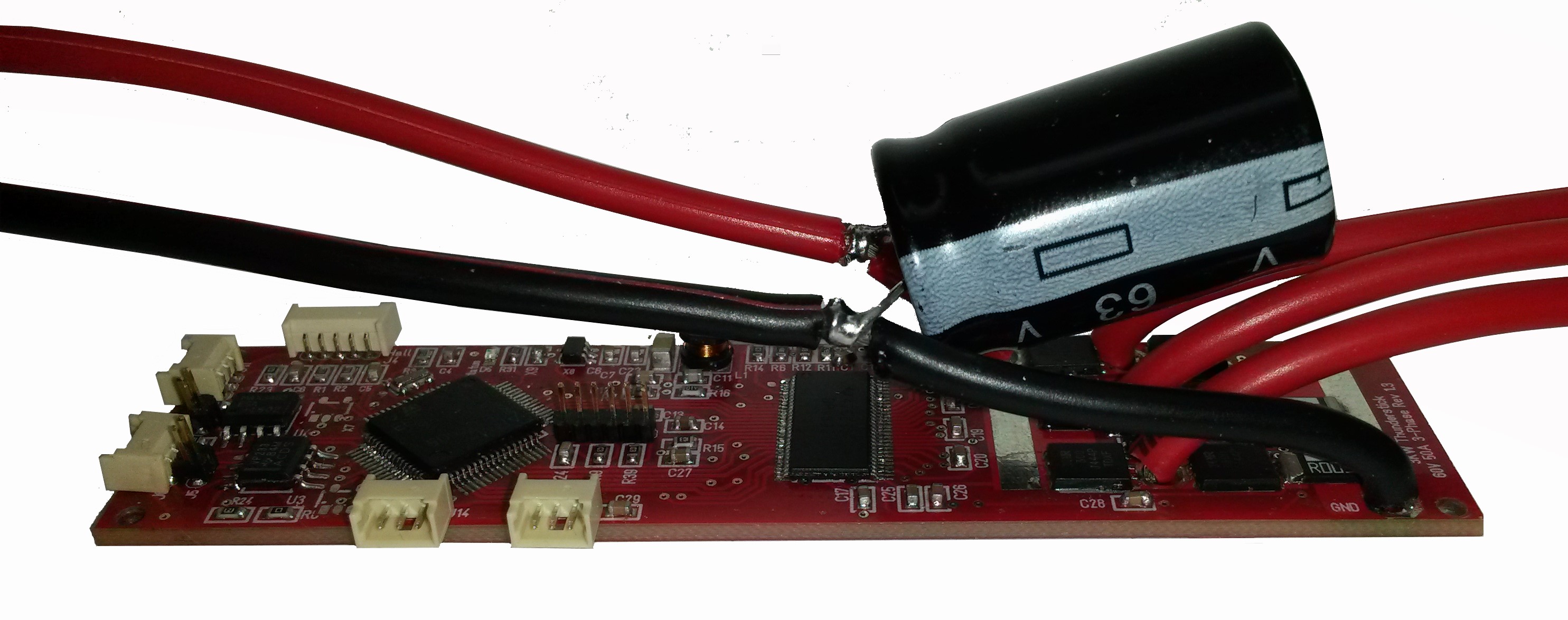

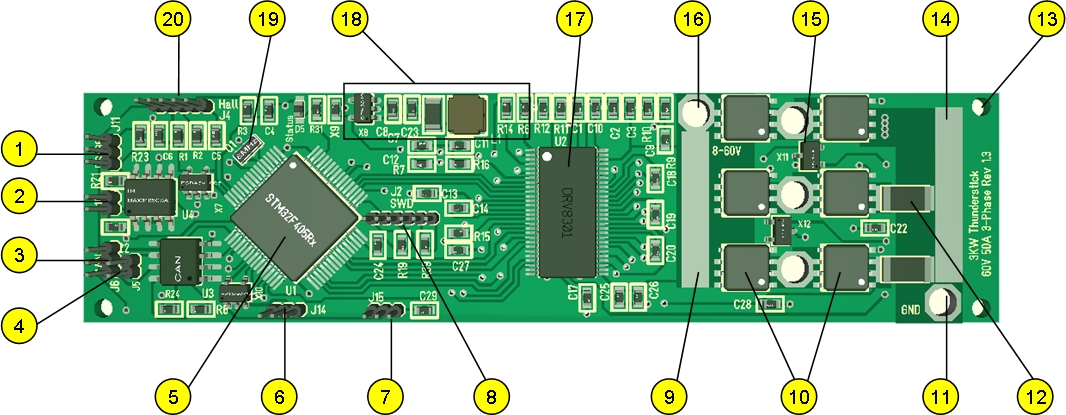

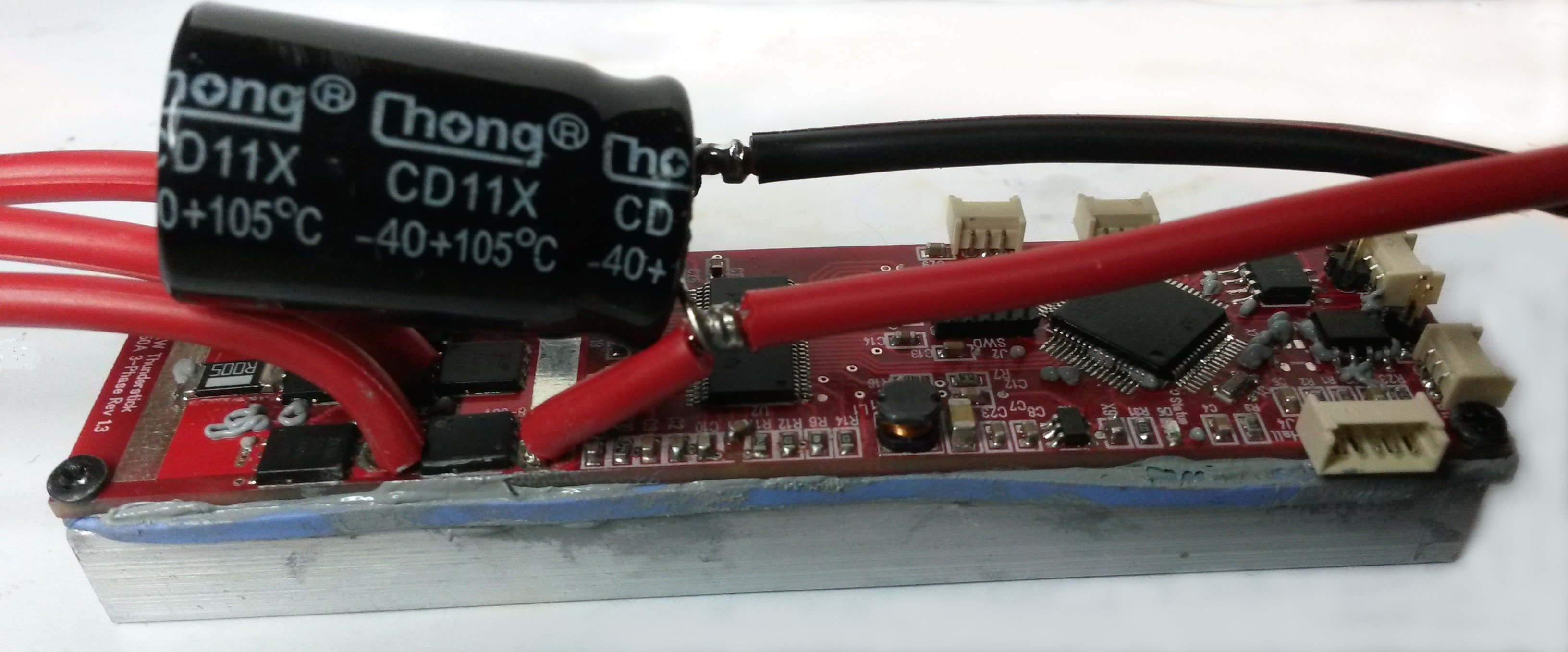

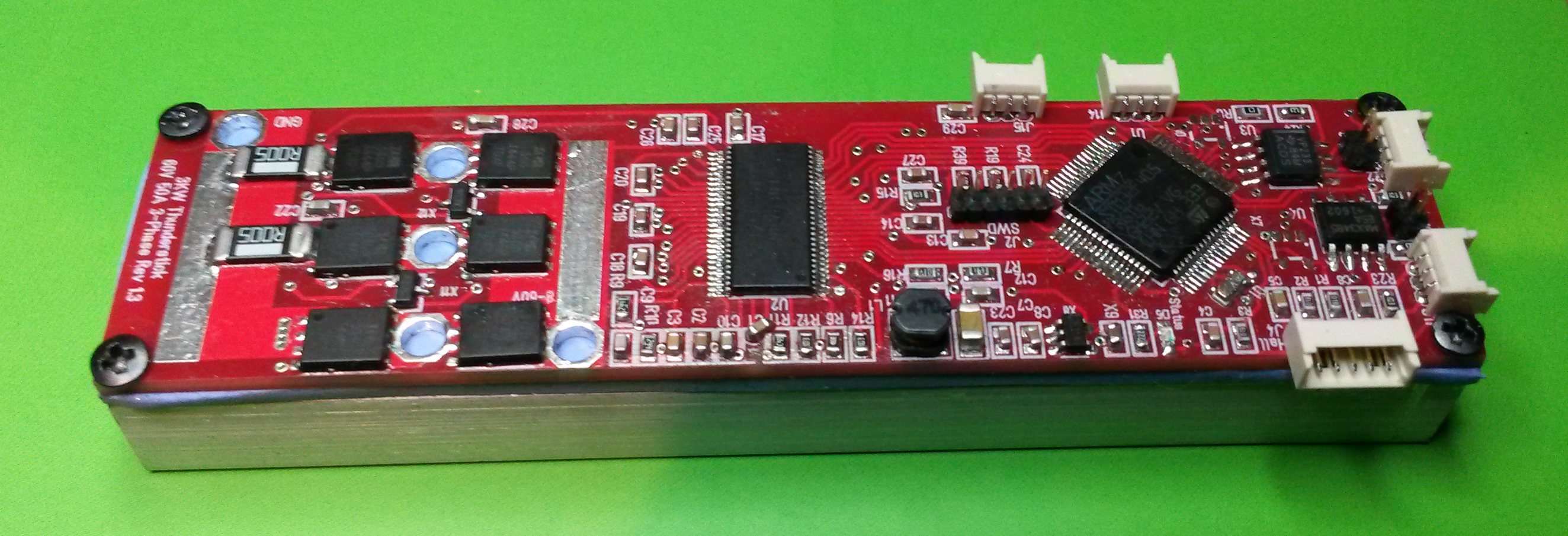

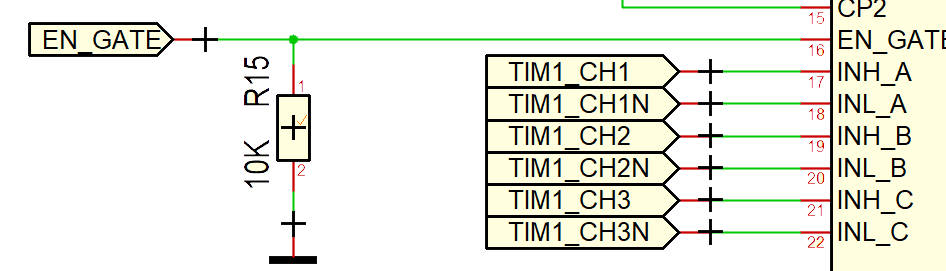

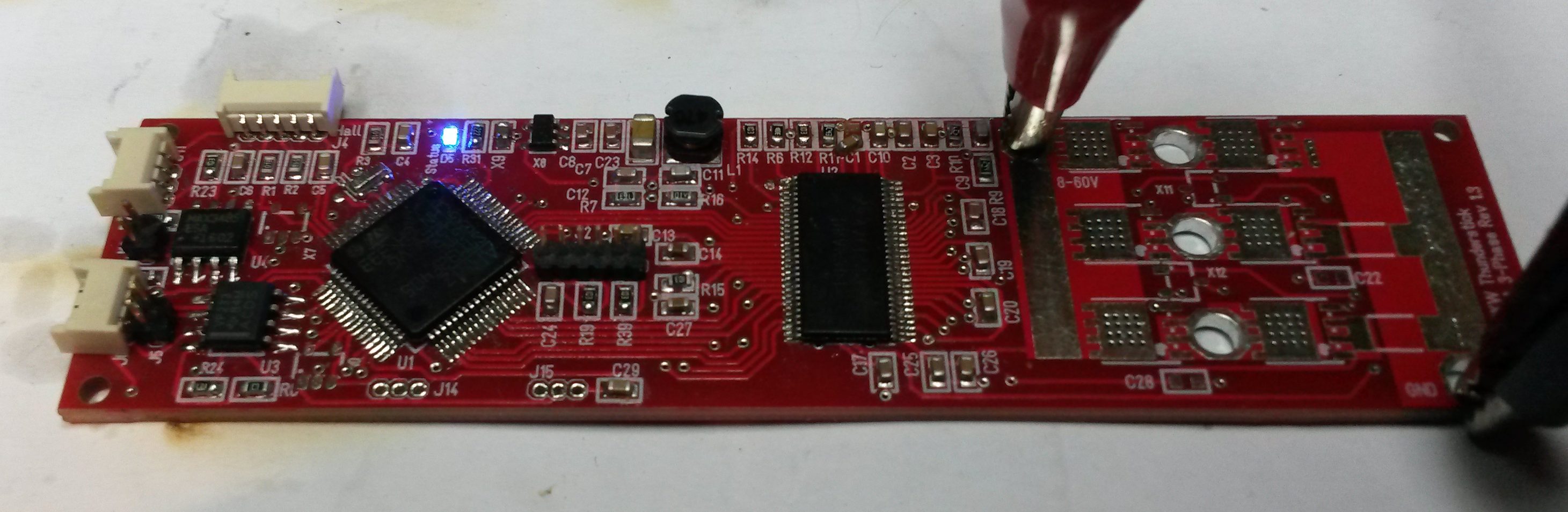

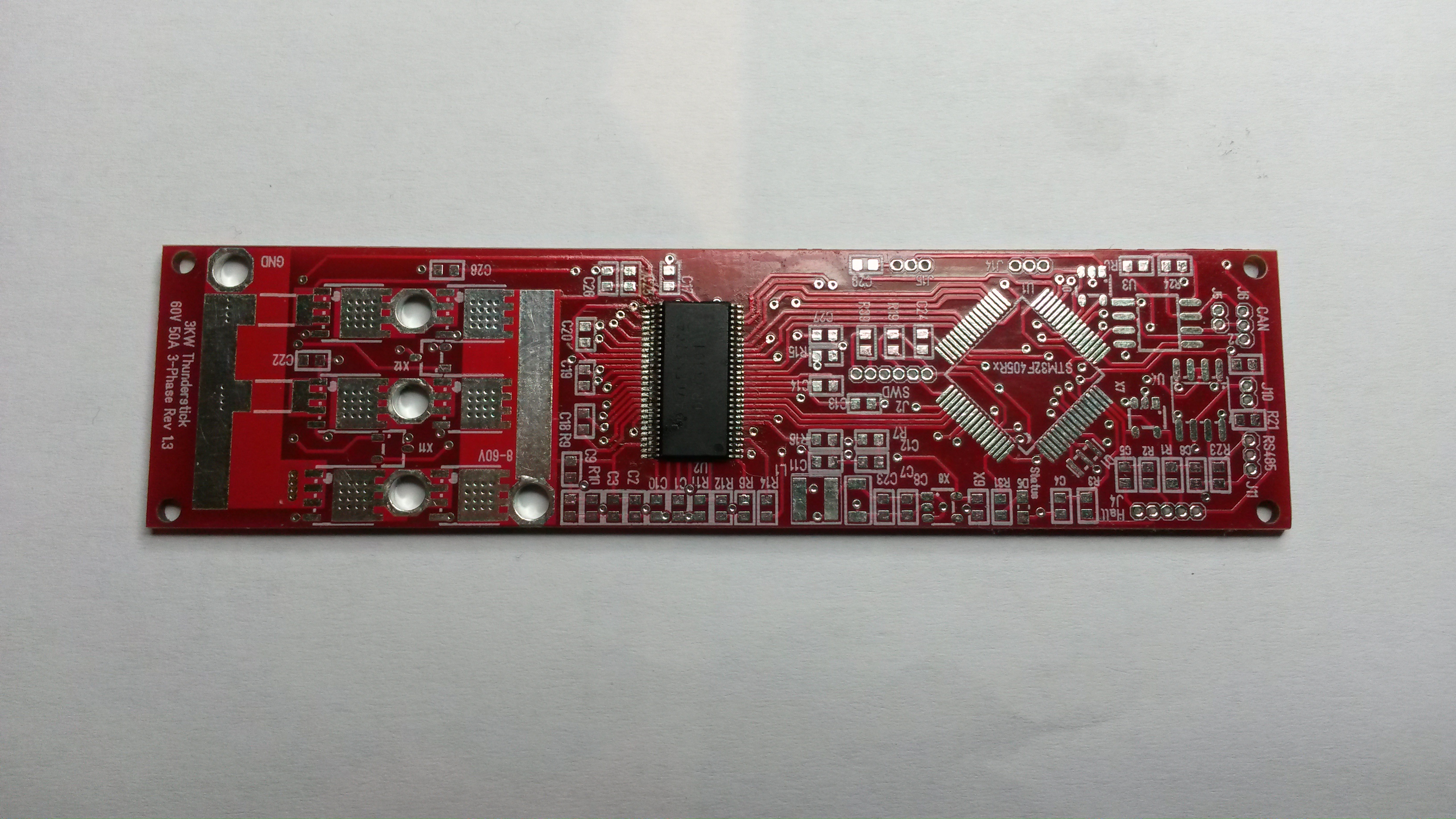

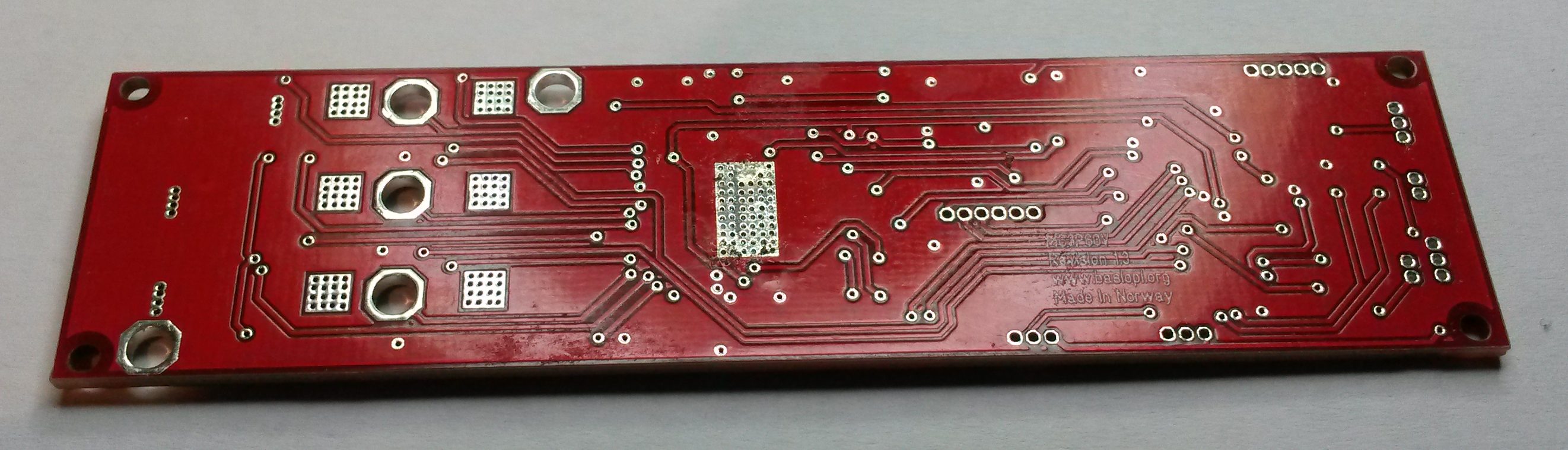

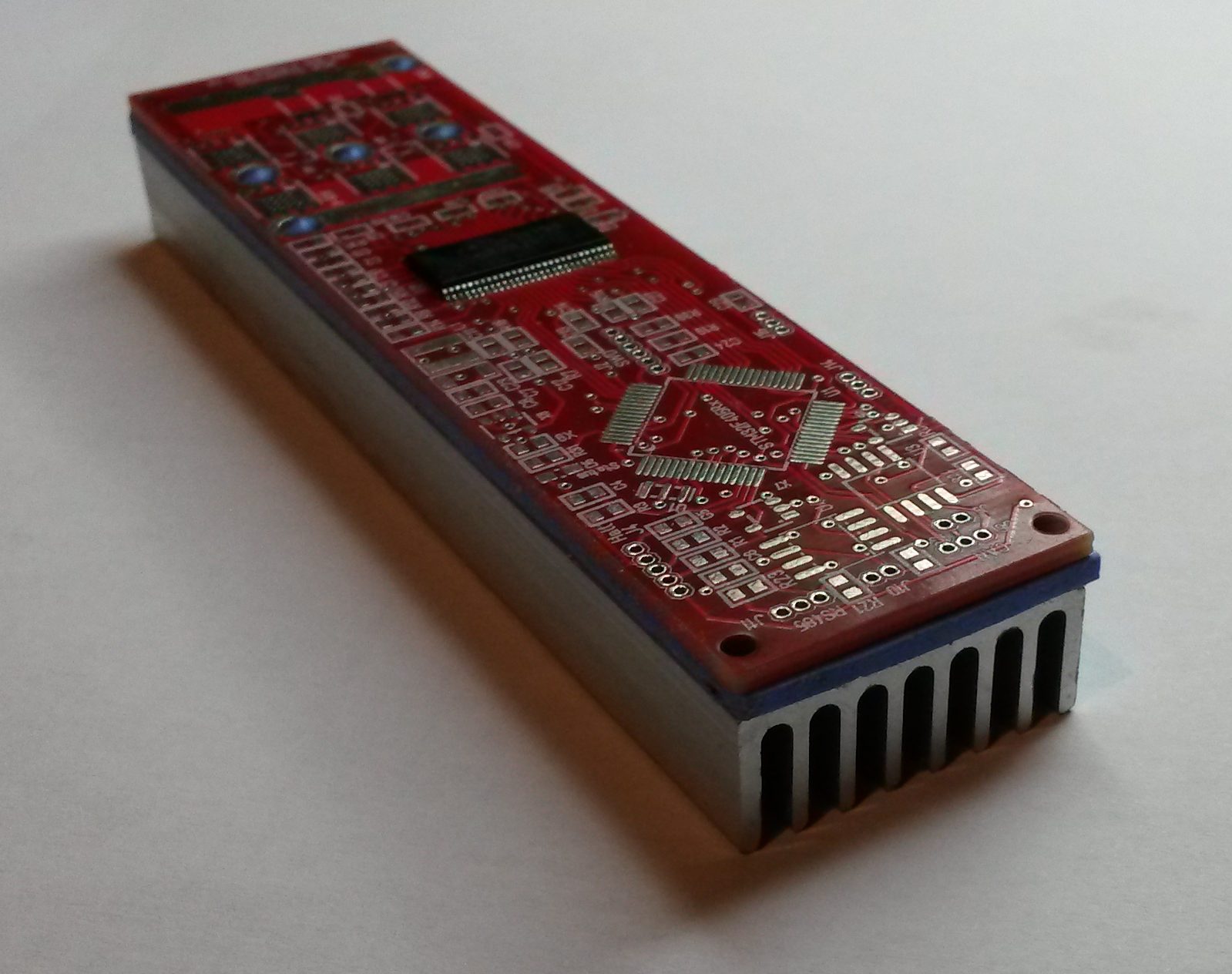

I have done a mistake by leaving EN_BUCK floating. The doc is a little vage around this area and I have copied that from other references that probably was not using the Buck Converter. The buck converter works, but it seems to give very little out. 168Mhz uses more than 84Mhz and power starts misbehaving. I tried to solder EN_BUCK to 3.3V, but a short-cut gave the magic poof of smoke on the MCU + DRV8301 looks weird afterwards – next board I assume – blah – I will make another attempt on the Buck Converter tomorrow, but if not I will just move on. This change is however the only one that might force a new PCB so far because it is very tight and hard to fix on the current PCB.

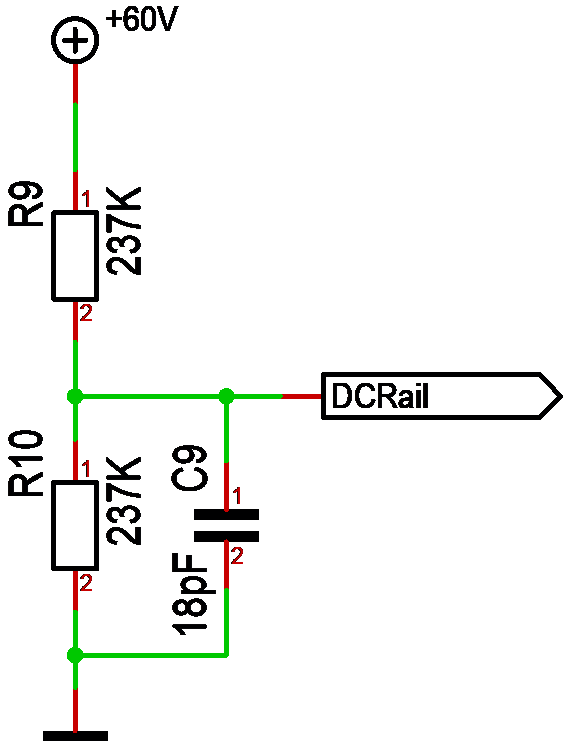

Looking at schematics I see I shorted 3.3V to PVDD and basically feeded 20V straight into 3.3V circuits – blah – it means DRV8301 probably is OK, so I could rip the board to test the buck converter alone – can’t do more damage anyway :). Looking at TI’s reference schematics I am convinced my mistake here is EN_BUCK. Using 3.3V is however not optional here since 3.3V depends on the Buck Converter. I need to make a voltage split from 8-60V that drag EN_BUCK above 1.25V. Voltage is clamped to 5V internally anyway I notice. That is sadly 2-3 more passive components.

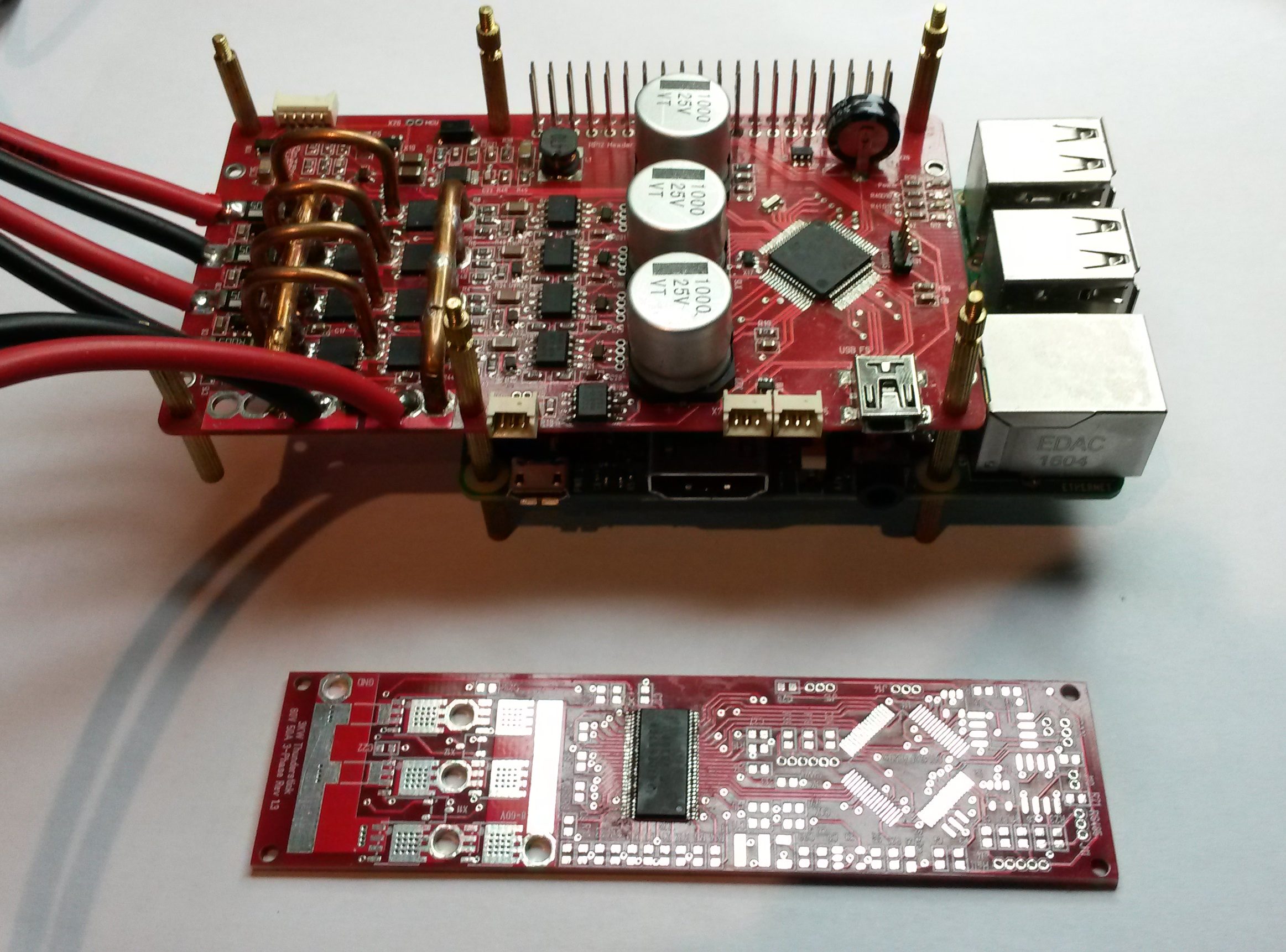

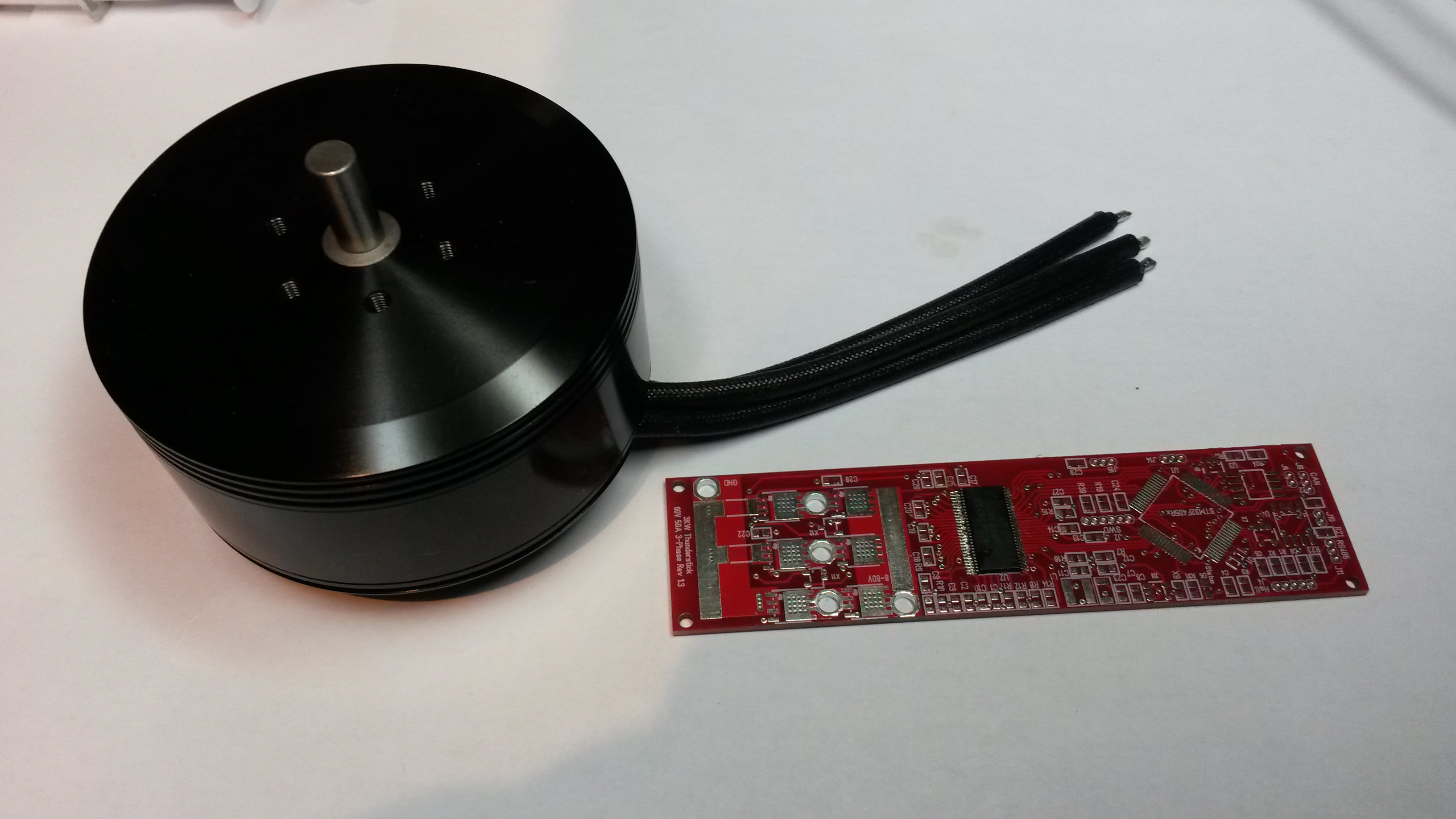

This design have some complexity so I would like to see PWM, Temperatures and Current Sensor logic before I order new PCB’s – I can do that by simply feeding the MCU from a 2nd PSU and avoid using the build in Buck converter. It is not ideal, but it allows me to test a bit more before I move on.