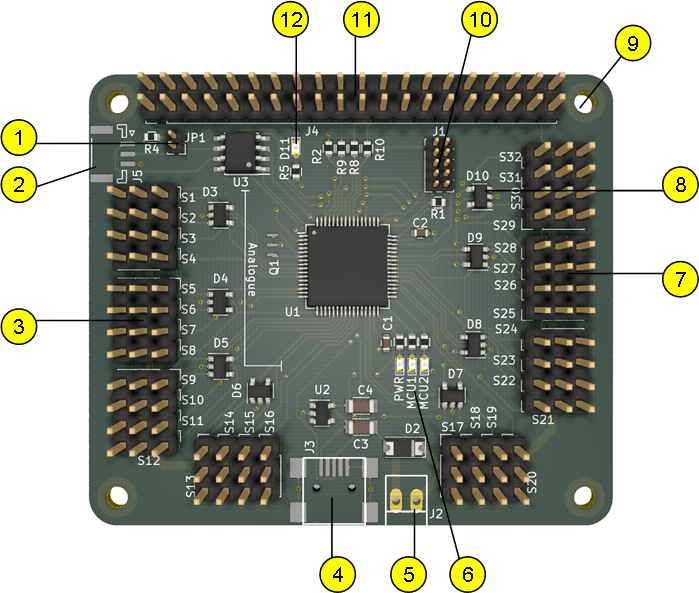

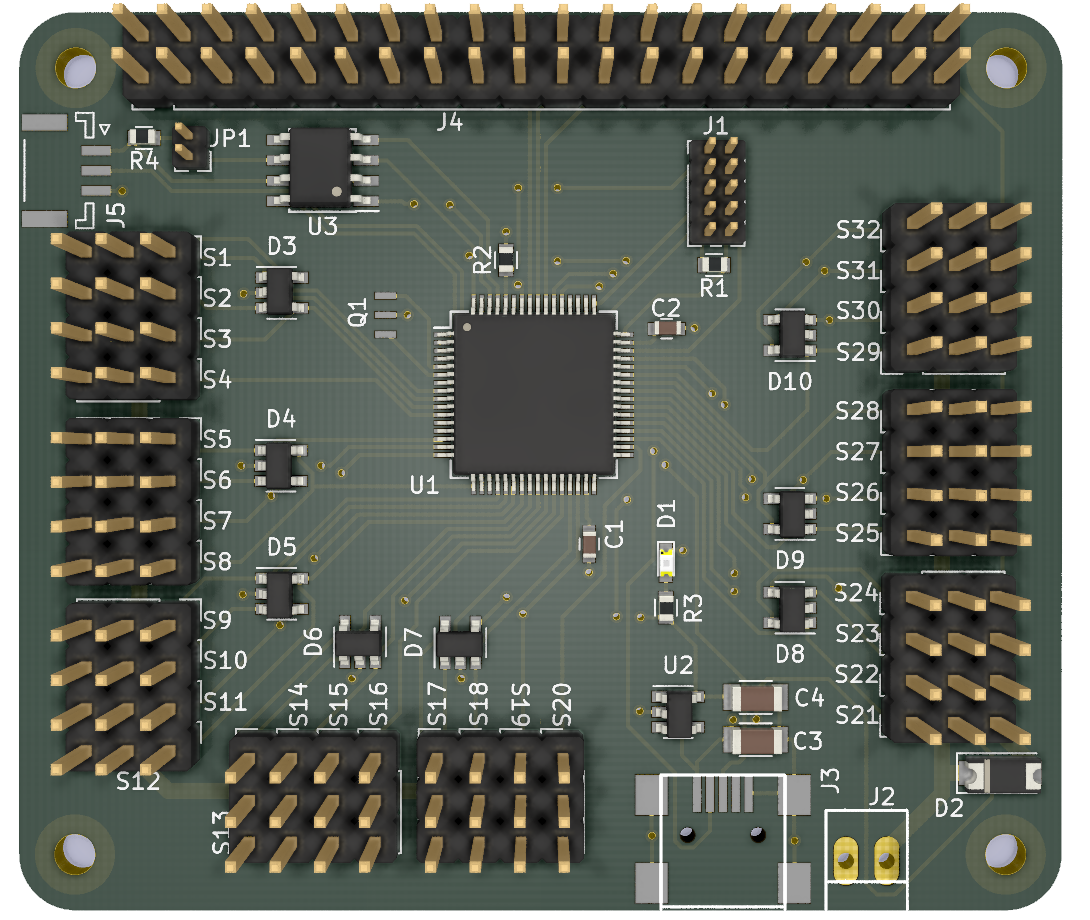

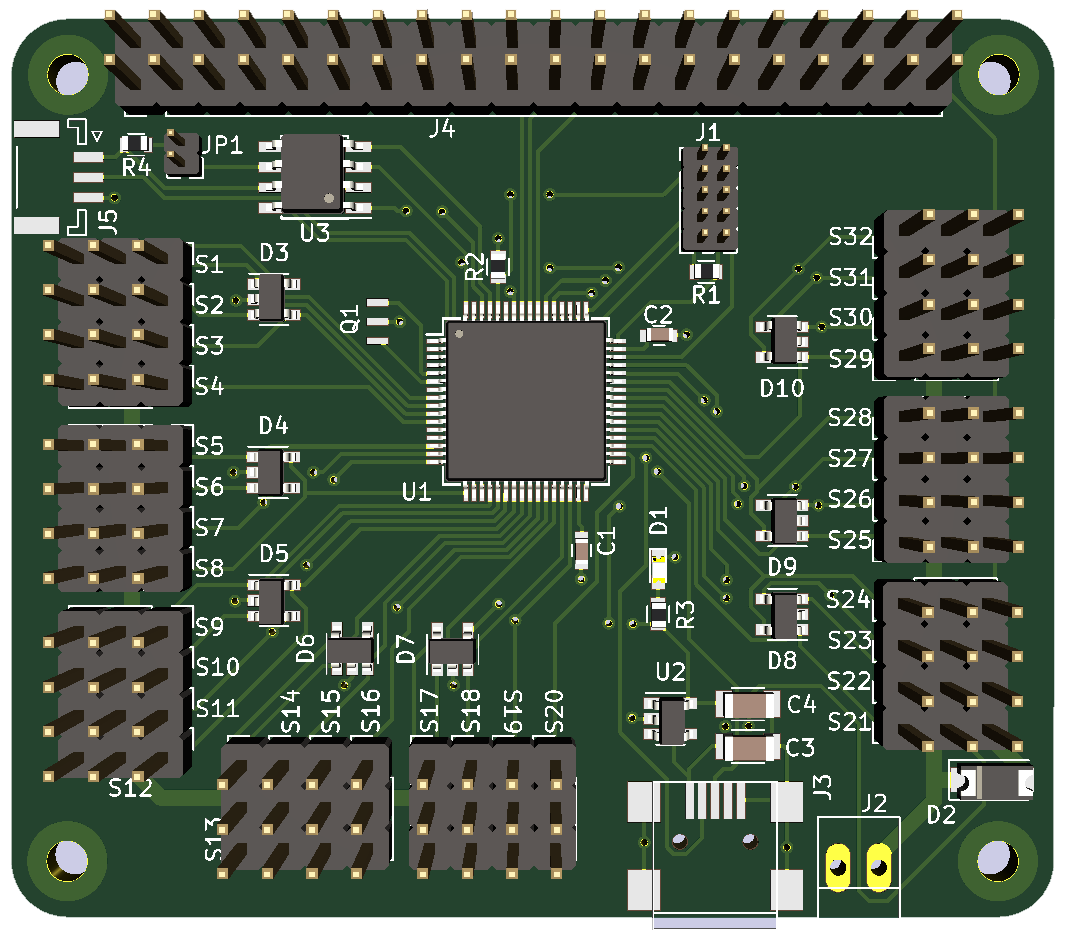

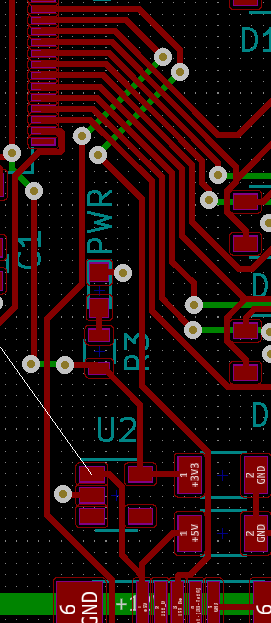

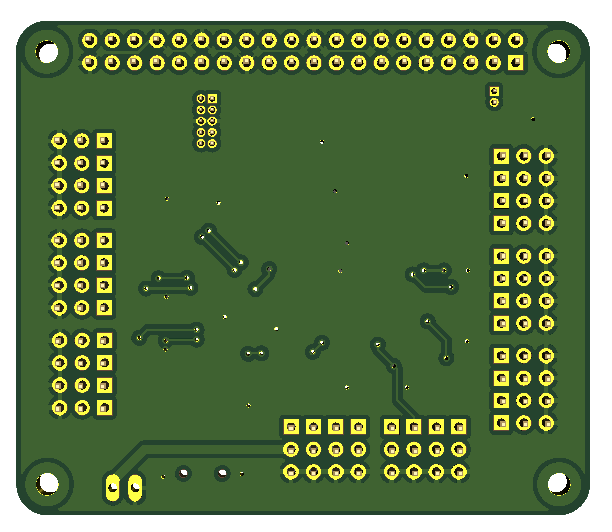

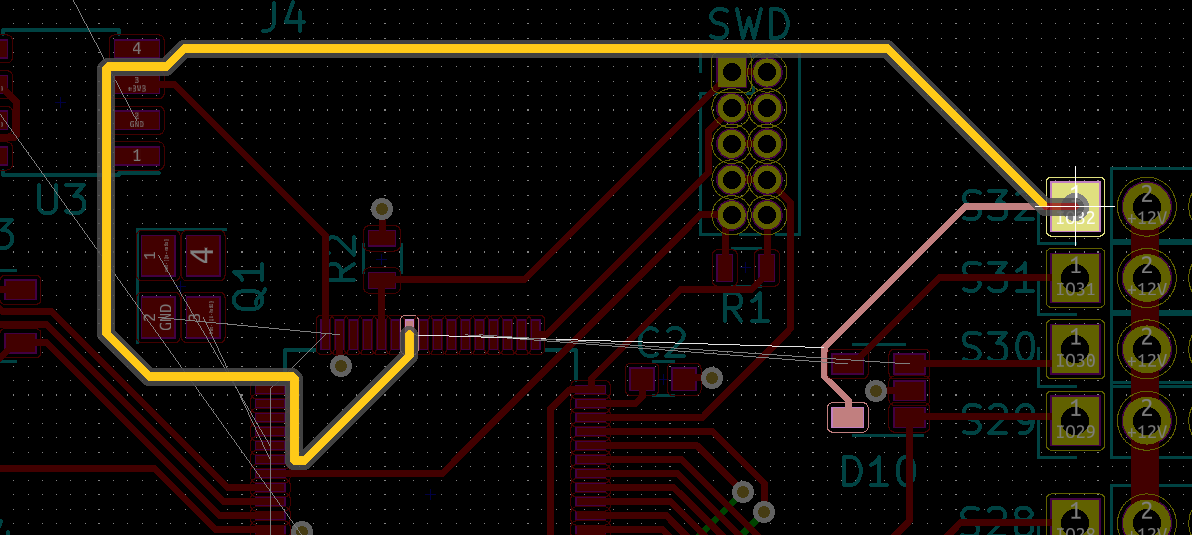

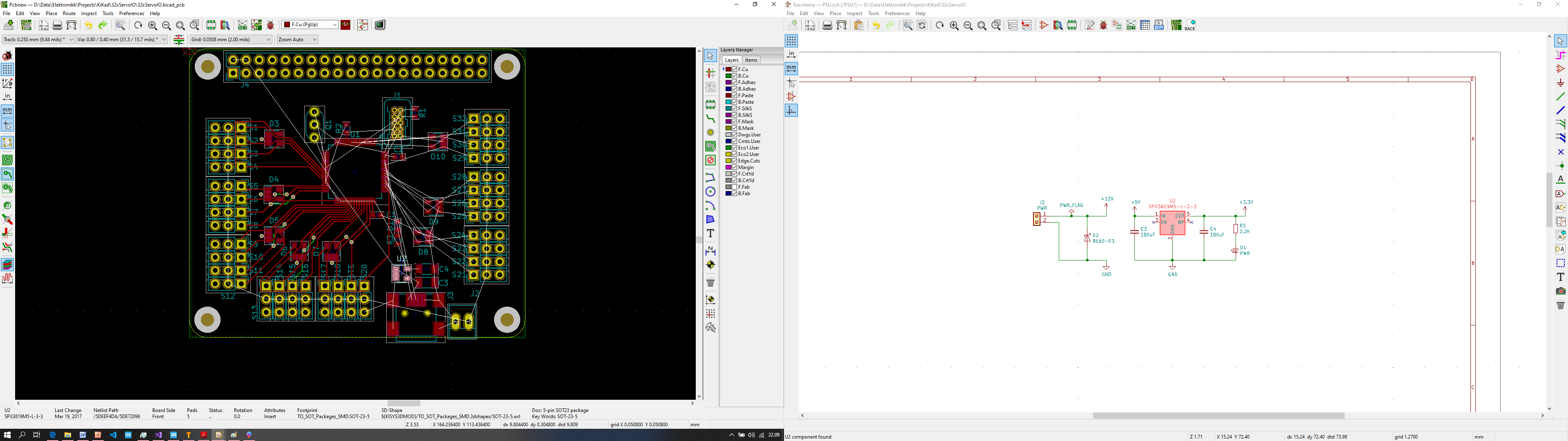

2nd Draft of my new 32xServo/IO Hat rev 1.4. Added the leds and missing SPI resistors + reorganized connectors at bottom. I notice that I need to add a capacitor to assist D2 (TVS) on the bottom + I want to add 2 jumpers allowing left and/or right array to be connected to 5V as supply +++ but, I am in no hurry to order this. As mentioned before I still have not fully tested rev 1.0 and it is mostly cosmetic changes. But, this has an obvious change that I put all analogue capable channels at left and all PWM only at right + to more care to use as many HW timer channels as possible. In the end I managed to grab 25 Hardware timer signals, leaving only 7 for SW bit banging.

- CAN 120 Ohm terminal jumper.

- CAN Port.

- 16 x Anague capable Servo/IO channels.

- USB Port. Great for development and stand-alone operation from PC as well as downloading new firmware.

- Servo power Connector.

- Leds 1 Power Led and 2 MCU leds.

- 16 x PWM only channels.

- 8 x 4 channel 5V TVS to protect MCU ports.

- 4 x drill holes in Raspberry PI 2 position/size.

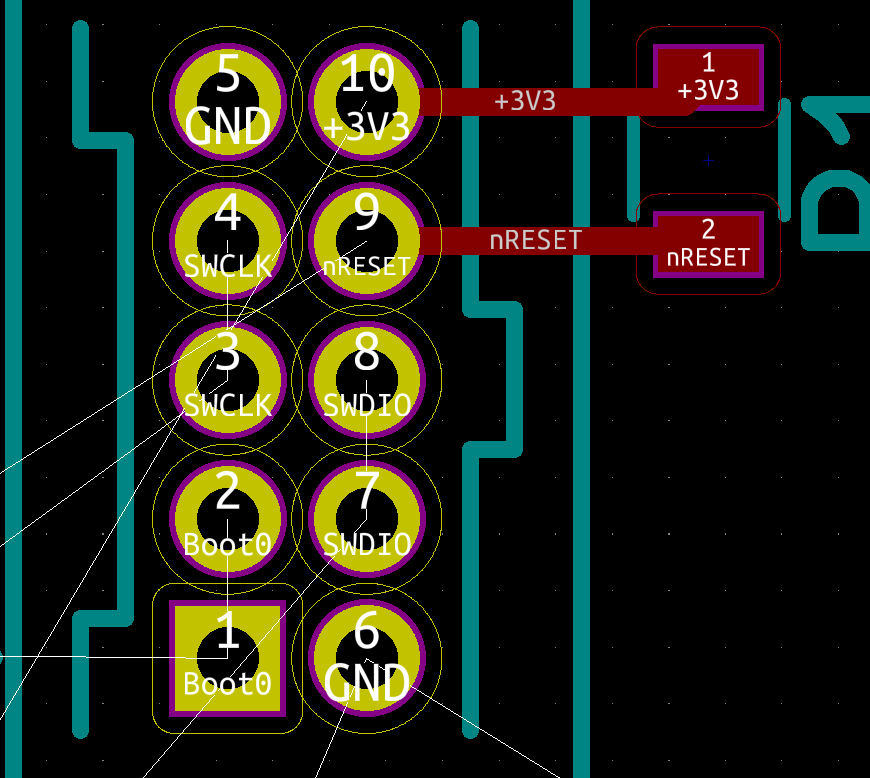

- SWD connector.

- Raspberry PI 2,3,4 Connector.

- Led for CAN port indication.

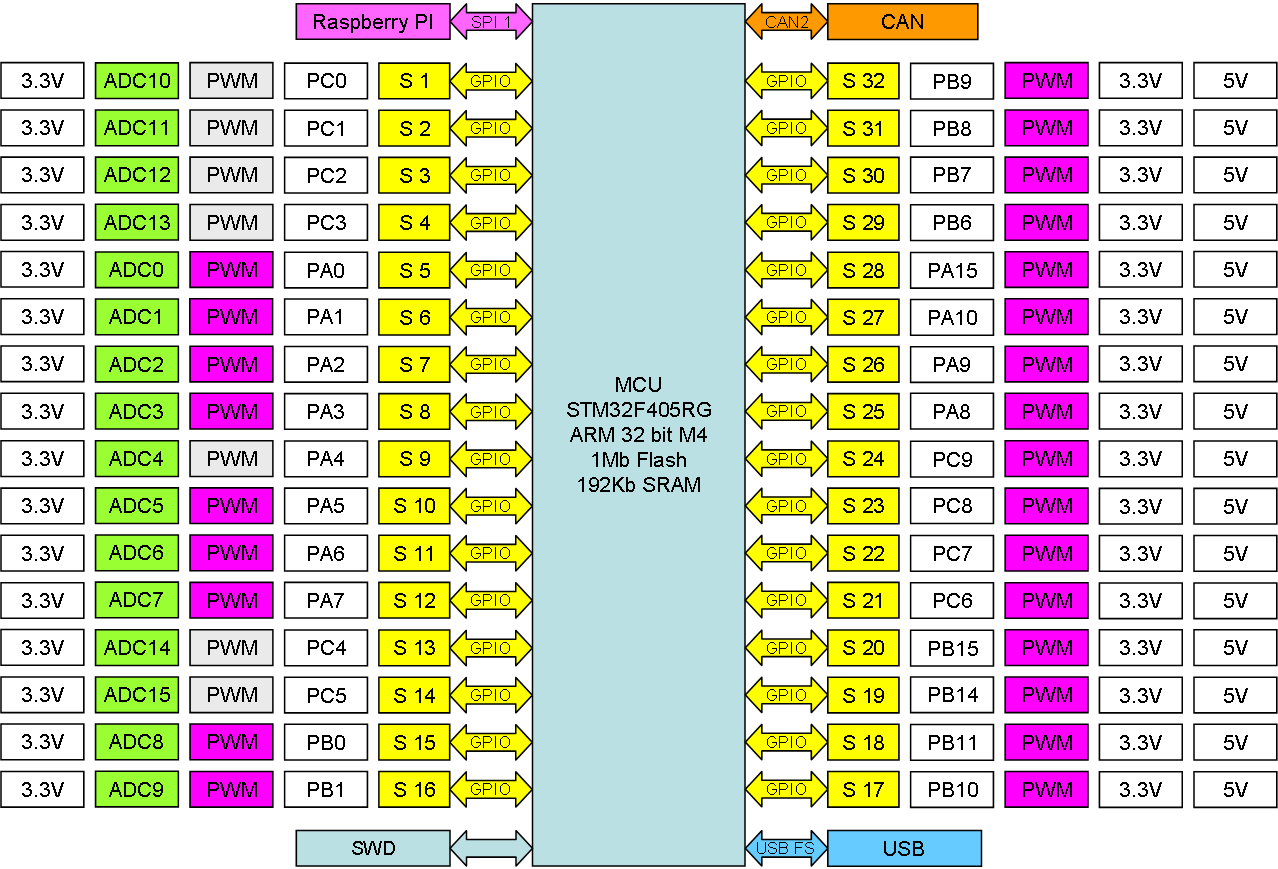

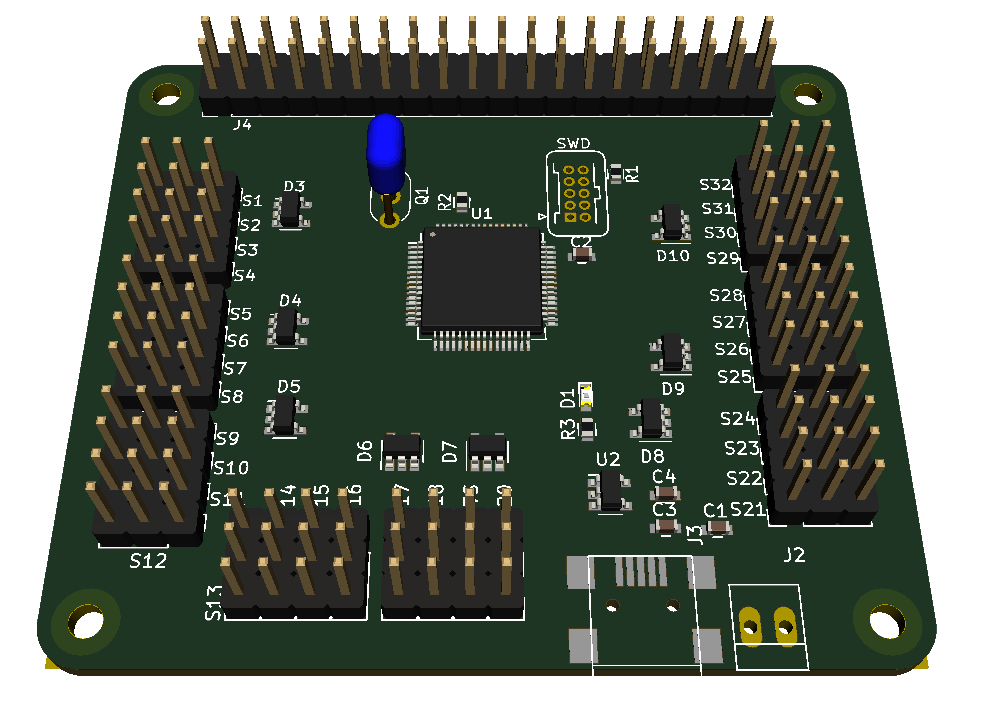

This block diagram show the actual channel per channel capacity and what MCU signal I used as base.

My challenge now is how to order a PCB? As mentioned before Norwegian import rules changes 1.Jan.2020, so I get slammed 20.- USD on a 10.- USD order. I need to find ways to avoid those handling fees, but it will take time before sellers abroad adjust and start declaring Norwegian MVA. If Elecrow declare MVA I would pay 2.5 USD for a 10.- USD order, if they don’t I end up paying 2.5 USD in VAT + 20.- USD in handling fee. One solution is that I wait and order many PCB’s together because the handling fee is the same. Doing this on PCB is doable, but on components it is close to impossible. The drawback is that samples will start costing 3-4 times if I can get them at all. Don’t worry, you will hear me whining about this for some time until I find a solution.