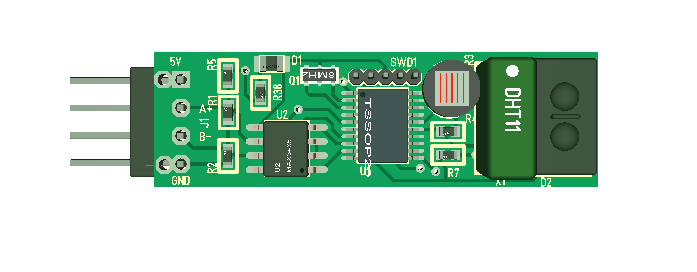

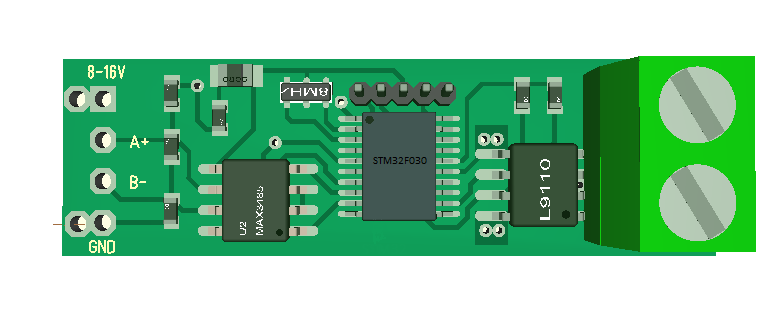

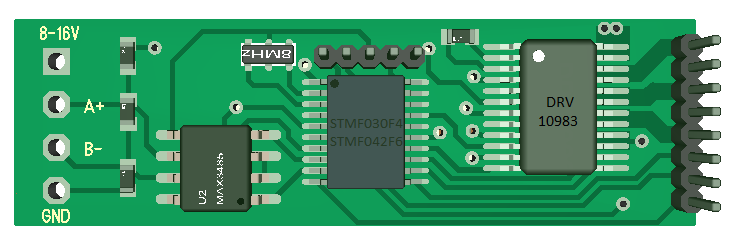

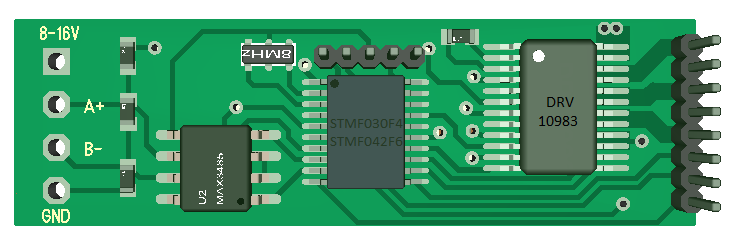

The BLDC Motor Controller above is 40 mm x 12 mm and runs a 3-Phase motor with/without hall sensors up to 2A on 8-16V input. The communication interface is RS485.

- STM32F030F4 or STM32F042F6 MCU

- DRV10983 Motor Driver with HEXFET’s.

F030/F042 in TSSOP20 package is among the smallest MCU’s from ST. I literally used every pin on the chip. It is a M0 ticking at 48Mhz and comes with 16Kb/32Kb Flash and 4/6Kb SRAM.

I actually did not pay this MCU much attention before I received a dev kit and realized that it’s 60% of the size of a LQFP48 package. I just had to try it out.

DRV10983 is a Motor Driver from Texas Instruments. This supports 8-28V, but my regulator is LM1117 supporting only 16V. I am using 3.3V only this time so swapped in MAX3485 as well. DRV10983 have a Bulk Converter supporting 100mA 3.3V, but I need to test if this is sufficient with transmissions on RS485. If it is I will drop the external regulator.

What impressed me with DRV10983 is that it has an easy to route package with GND, Power, U, V and W on double pins. It also have a two pin input driving a 3-phase sinusoidal scheme making it easy to use from any MCU.

- 180 deg sinusoidal vector algorithm.

- fault detection.

- 3 phase motors up to 2A.

- Analogue/Digital PIN interface.

- I2C interface.

- EEPROM to save motor parameters.

- Bulk Converter with 100mA 3.3V available.

- Current/BEMF sensors.

- Over current protection.

- Temperature protection.

- Speed Control.

- Direction Control.

- Start/Brake Control.

- Acceleration Control.

Bare over with me if I got some of this wrong, but DRV10983 is worth a look if your looking for an easy path to a miniature BLDC Motor Controller that cover 12-24V.

The STM32F030 or F042 is a bit small for my taste, but don’t worry I will be making a version with F303 and some breakout boards based on some of these drivers.

Note that Hall sensors on this is an optional position Counter only. Hall sensors are depending on a counting mechanism and I hope I can get the timers to do this. The input lines for Hall can also be Connected to a resolver. This part is however not Critical for running the motor.