RAMPS are great for driving stepper motors for 3D printers because they are small and cost around 1.- GBP each. They are quite capable of controlling steppers up to 2A with some heat sinks, but controlling steppers above that is a challenge. Available controllers are large and tend to be expensive.

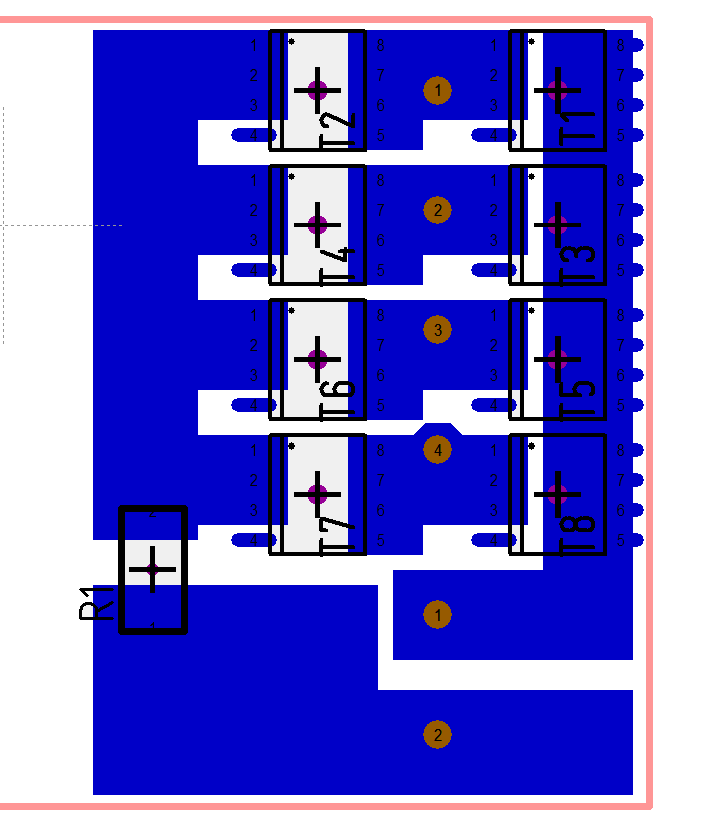

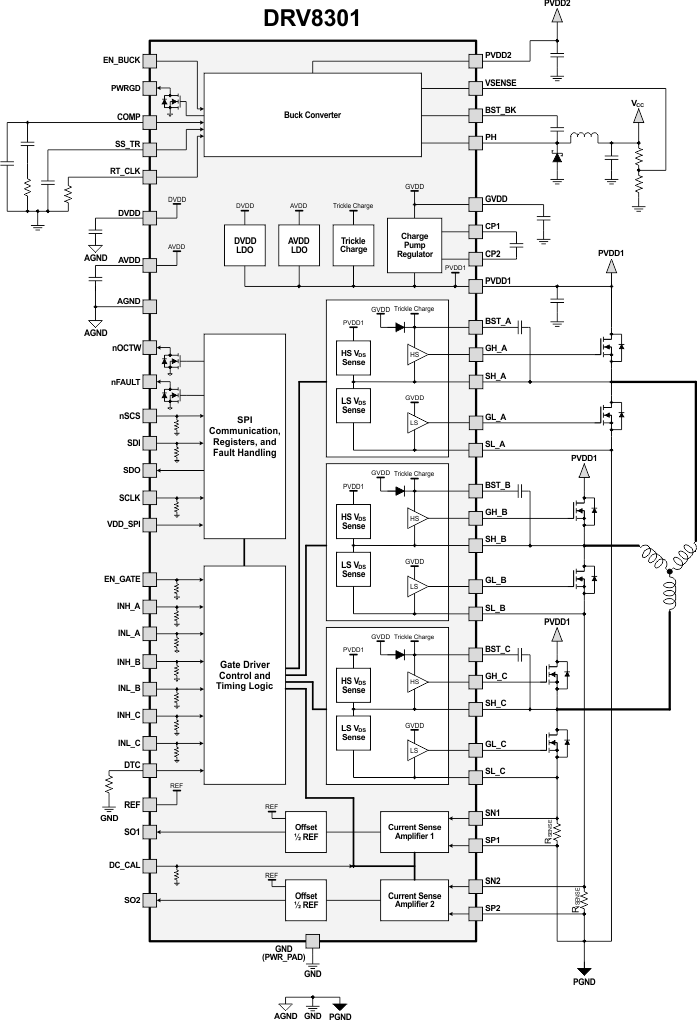

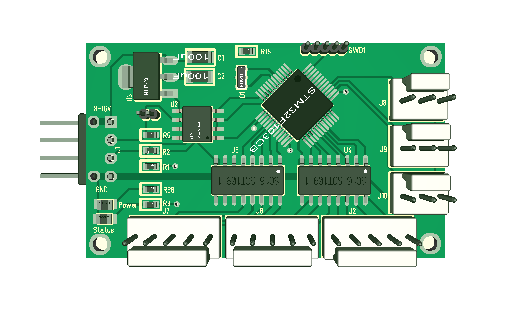

Looking at the 3-phase motor controller it is quite easy to add a 4th half-bridge to control a larger stepper motor up to 20A. The concept is simple using a discrete gate driver, two HEXFET’s and a dedicated MCU. On a driver this size you also want current sensing and a bit of protection logic. If we design for 12-24V it means we are designing a 500W stepper motor. My target is actually up to 10A, so a 20A should give me some margins.

I also want to study a gateway to the Mach 3 or similar standard. This is something I currently know little about, but I am told that this standard is important as it enables existing top-side systems to be used. My first idea is to create a RPI GW Hat to connect easyIPC and Mach 3, but I will return to the details later.

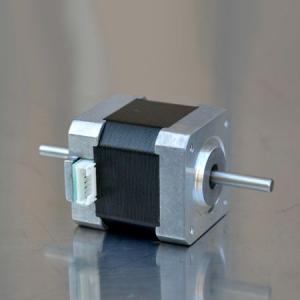

Lets look at some stepper motors (Pictures from various internet sources) to get an idea:

This is a smaller Nema 11 using 0.67A. The 6 wires means we have 2 phases where each phase are two coils in series. I need to experiment a bit with this as well as test on the 28BYJ-48 that uses similar wiring with 5 leads where the two centre ones are connected. Driving motors this small is well within more cost optional solutions, but we should be able to run this as well if needed.

This is a smaller Nema 11 using 0.67A. The 6 wires means we have 2 phases where each phase are two coils in series. I need to experiment a bit with this as well as test on the 28BYJ-48 that uses similar wiring with 5 leads where the two centre ones are connected. Driving motors this small is well within more cost optional solutions, but we should be able to run this as well if needed.

The Nema23 above is rated at 3,5A and typical for our target range. The same for the Nema34 below rated at 5,5A.

The Nema23 above is rated at 3,5A and typical for our target range. The same for the Nema34 below rated at 5,5A.

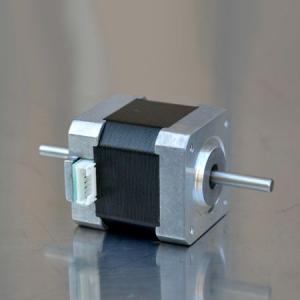

This is a classic Nema17 (below) with double shaft. You get these below 10.- USD with single, double and hallow shafts. This one have a 0.44Nm holding torque using 1,5A. Again well within the capababilities of a RAMP.

This is a classic Nema17 (below) with double shaft. You get these below 10.- USD with single, double and hallow shafts. This one have a 0.44Nm holding torque using 1,5A. Again well within the capababilities of a RAMP.

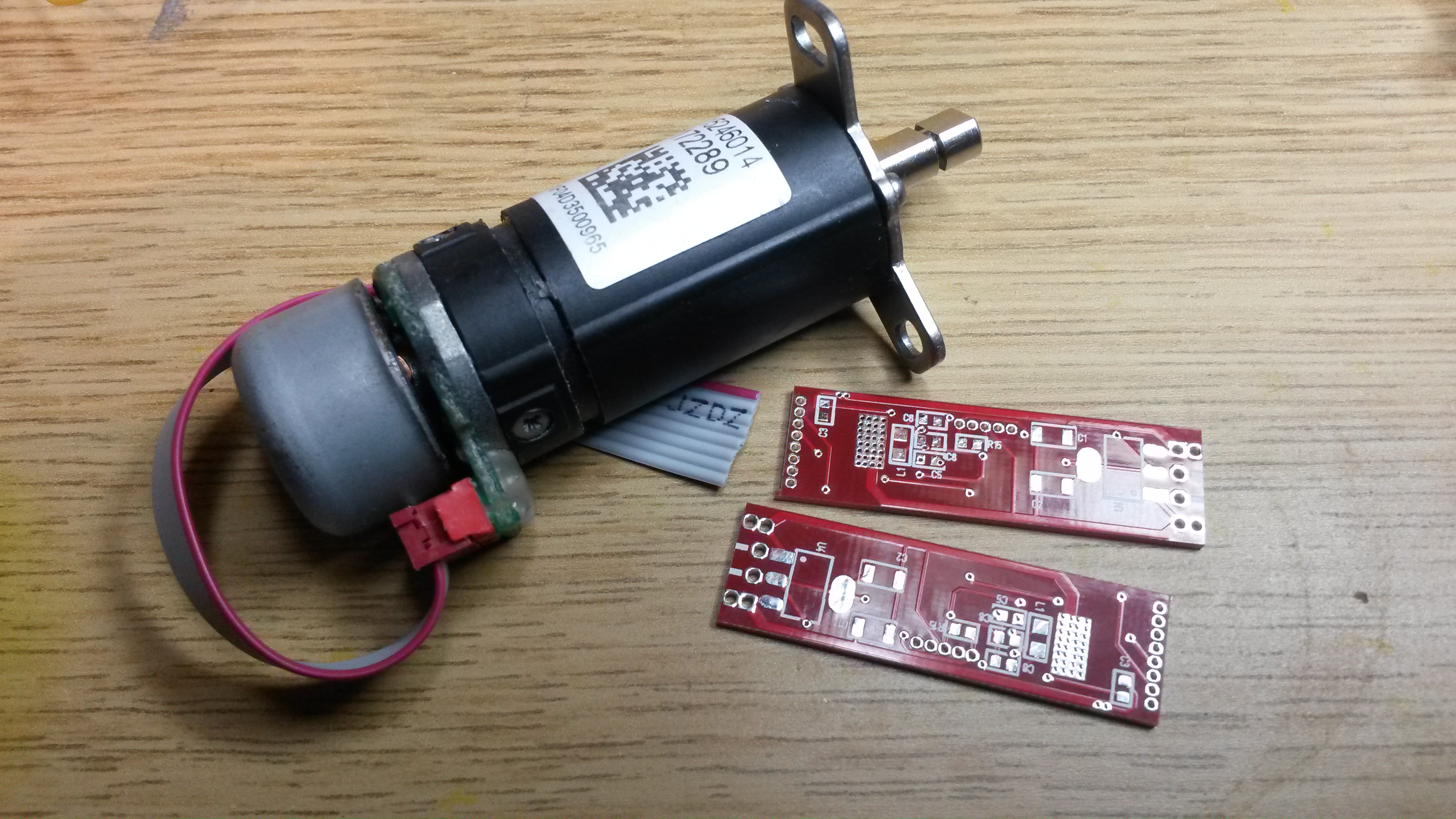

Yet another Nema23 with a gearbox mounted (below). Rated to 4A. Looking at various sources I find that the majority of steppers are within the range of a RAMP and very few above 10A. So a low cost controller targeting 0-10A (max 20A) should be a great addition to what currently is out there.

Yet another Nema23 with a gearbox mounted (below). Rated to 4A. Looking at various sources I find that the majority of steppers are within the range of a RAMP and very few above 10A. So a low cost controller targeting 0-10A (max 20A) should be a great addition to what currently is out there.

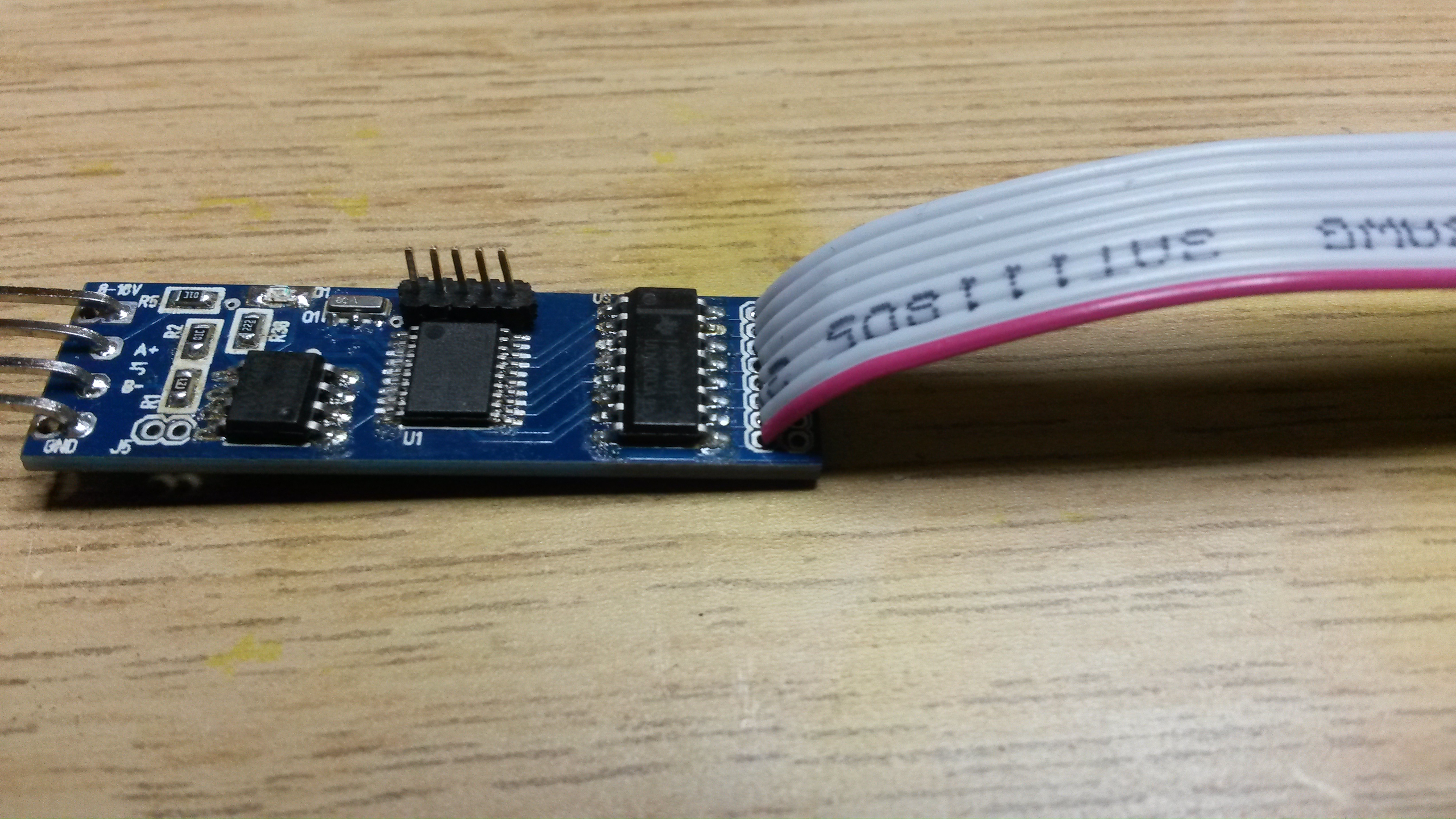

As for wiring we should allow a stepper 4,5 or 6 wires where the 5th and 6th is +, – or not used. Minimum voltage should be 12V. We obviously need end points and I would like to add some temperature sensing as well as support for encoders. I will have a look for pre-amplifiers for this, but so far I have not seen anything worth mentioning so I am planning discrete gate drivers. This is not always a disadvantage, but a modern pre-amplifier usually implement some logic that we otherwise need to code.