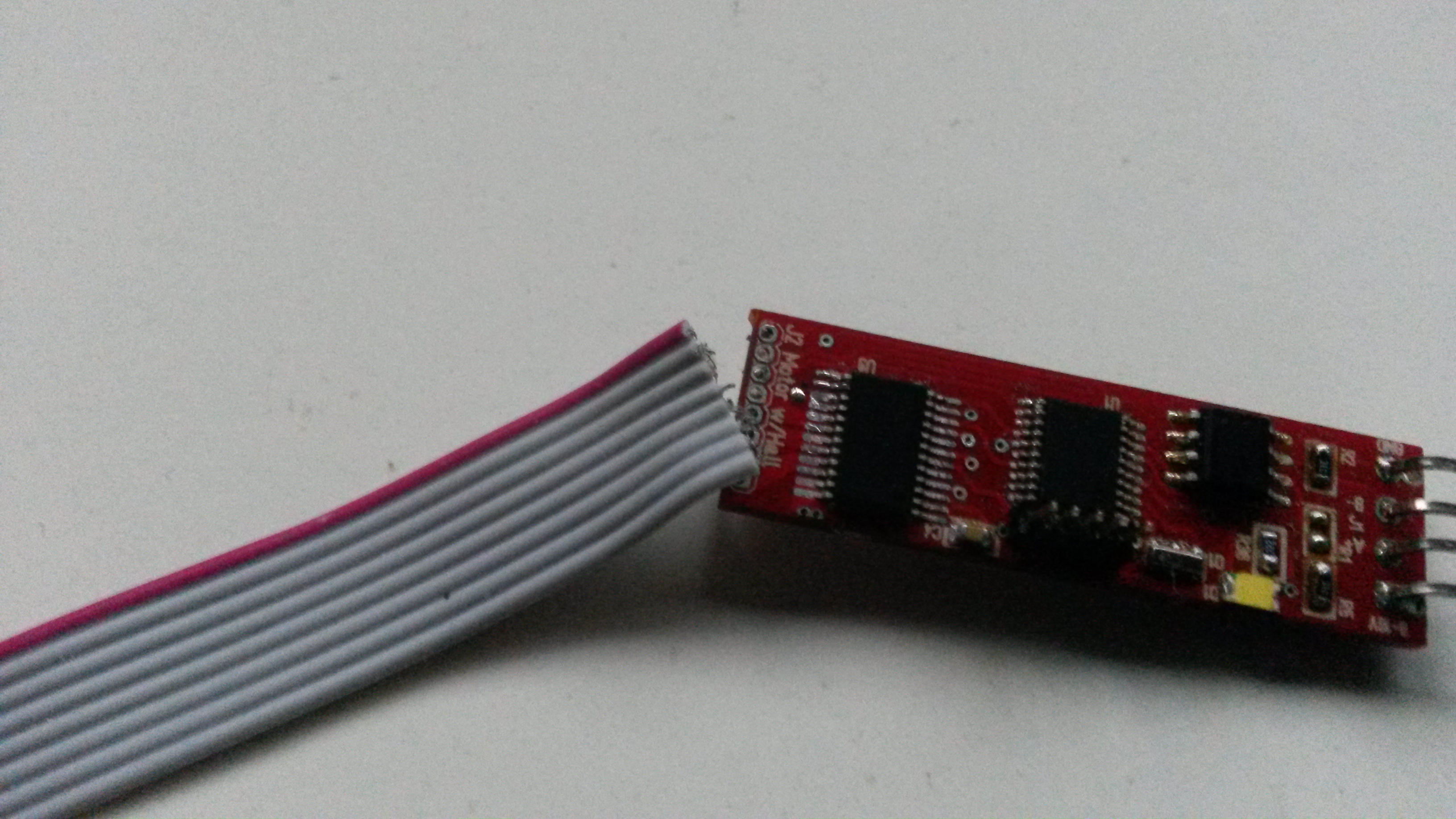

I was initially quite happy with the way this cable fitted, particularly as I found a trick on how to solder these. But, this is how it looked after having fiddling with it for a day. I could add a proper micro match connector, but they are a bit expensive.

Another solution is to add a cable holder on the PCB at the end to avoid that handling the cable is exposed as stress on the solder points. In this case I need this cable since I am connecting to a motor with a special connector, but for the micro PWM driver that have the same issue it might be an option to simply use 2.54 pitch connectors. It is nice to have things small, but they need to be functional as well. The challenge is to find a solution that is practical and don’t drive size or cost to much.