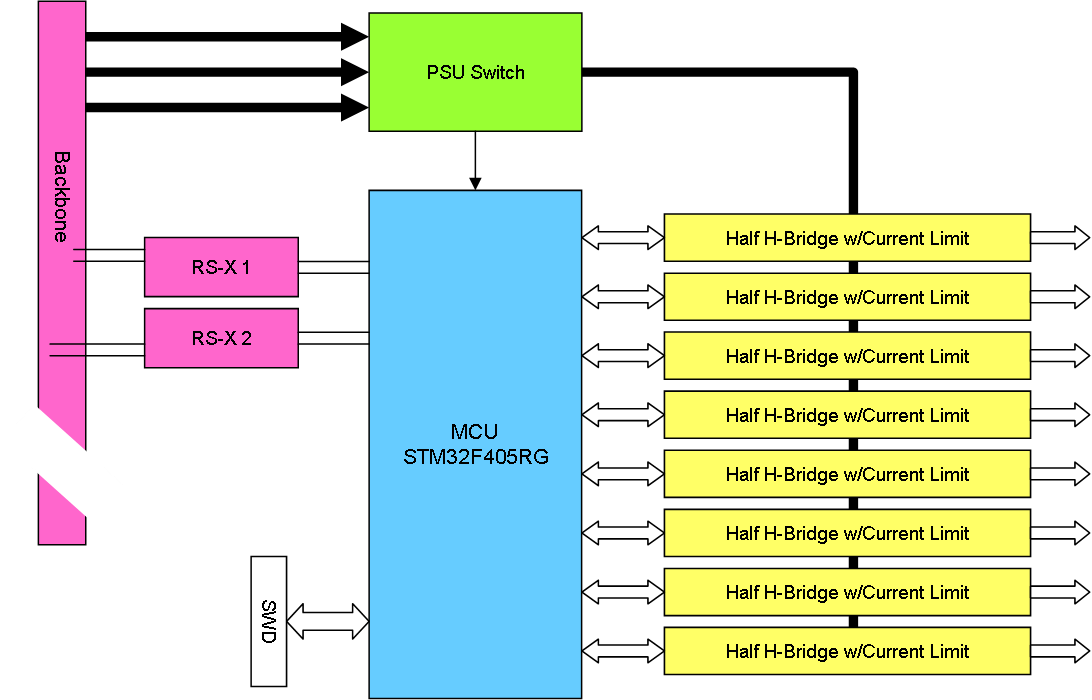

This is an old PWM Module drawing. The idea is to create a PLC module that can handle 4,6 or 8 PWM channels with 12/24V and up to 3A. I know from testing of MC4X15A that this is very doable as soon as I solve the current sensor on the channels.

The usage here is to drive solenoids, dc-motors, even stepper motors. An old hydraulic actuator will typically be driven by 2 x 24V PWM signals pulsing at very slow rates using ca 1A per channel. And yes, I can drive 2 x 3 phase motors as well since I will be using the 2 Advanced timers With 4 PWM channels each. Using the same design as on MC4X15A I actually have an option for higher currents, but this needs to come from a singlle PSU Source and I believe a max rating of 10A in total is reasonable and doable. For higher currents we need to consider specialized designs.

I have a few advantages compared to the motor controller as I have no usage of the BEMF signal and “only” need 8 PWM signals and 8 ADC signals as interface. IR2103 can combine H&L since L input is inverted and as such be driven by a single PWM pulse. I am, not able to offer 5V PWM since the gate drivers and MOSFET design requires a minimum of 10-12V to work.

Another advantage is that 12 & 24V is provided directly on the backbone, so I don’t need any PSU logic on the Board (except a bit of protection logic). I need to look into routing Power from the backbone to the MOSFET’s and I need to squeeze each channel into 40mm x 6mm to achieve 8. But, it’s no disaster if I reduce to 4 channels. In fact I actually consider making the PWM channel an click-on sub-board – not sure.

I will start on this as soon as I have a solution to current sensing that I like. The advantage with the PLC is that we also have 5V available and loads of the attractive sensor chips need 5V. One I would like to test is MAX9918 because it can handle -20 – +75 Voltage making it attractive for a 60V BLDC Controller later. But, I have not given up on the INA210, INA213, INA214 family yet. The INA family is ranged 26V so they are attractive for a 24V design. Their size is a pain in manual assembling, but it is a blessing in design – if I can get them to work.

The interesting part here is that we take the driver from a BLDC motor, simplify it and re-use it. The result is a very advanced and capable PWM channel.