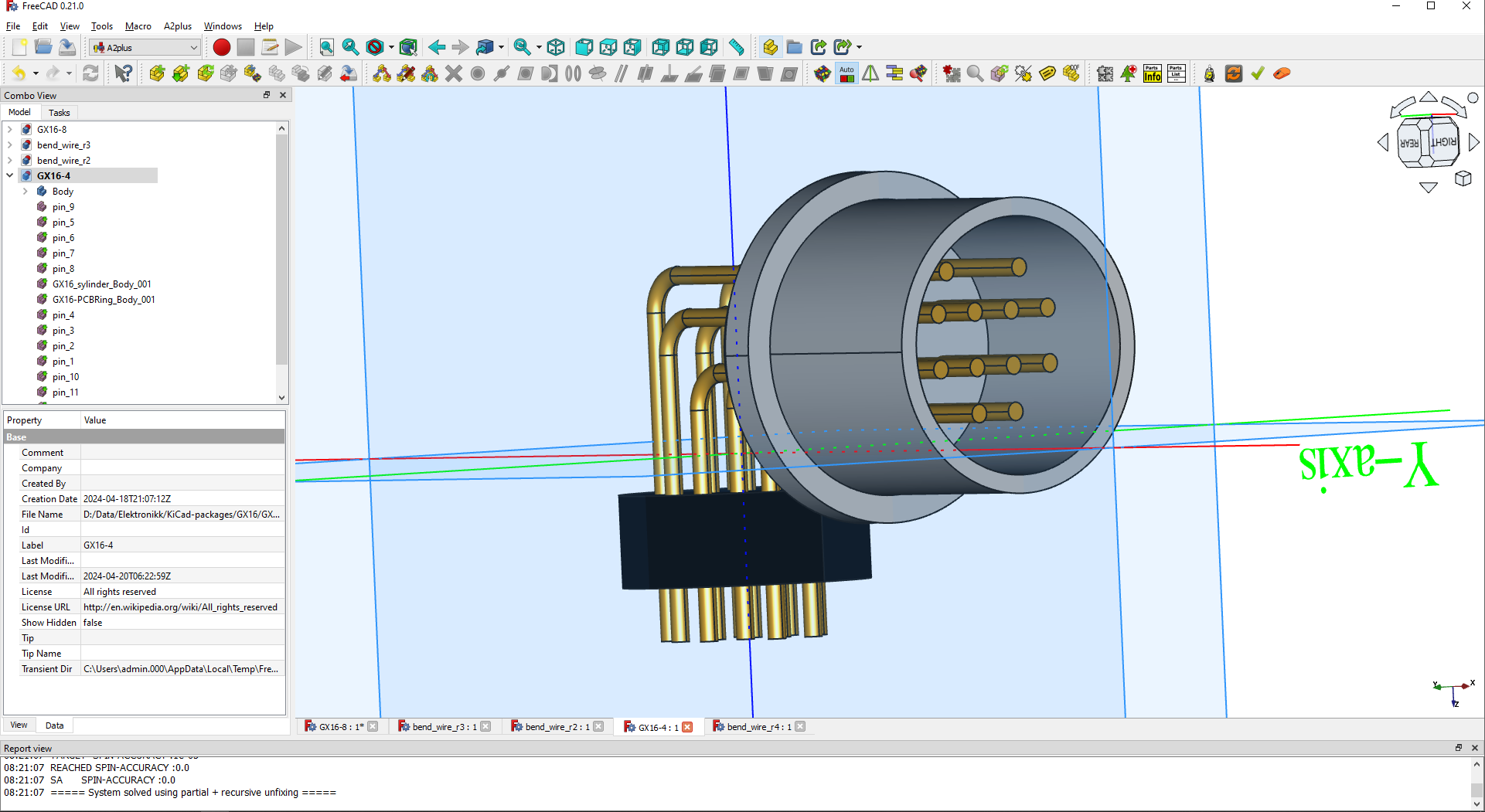

I fancied using GX16 connectors in a project since they are low cost, robust and can be made water proof. I found 2,3,4,5,6,7,8,9,10 and 12 pin versions with bend pins so they can be mounted directly on a PCB and fixed to a panel. But, what I did not find was 3D models for KiCAD, so I made my own. To draw the 3D package I used FreeCAD that is becoming increasingly usable. GX16-12 is illustrated below. After drawing this you export it as a STEP file and import it on the footprint in KiCAD. One trick I often use is that I focus on important details like footprint and in this case distance to panel. The rest is nice to have – the sylinder have a M16 screwing and a flat area on top that I have not added yet (saving some time for now).

Assembling in FreeCAD is not so bad, but you need to think about how you build your parts. In this case I have a part GX16-12 that uses multiple sub-parts. It was easier to assemble that way using an extension “A2Plus” + once one version was drawn it eas fast to make the other pin versions as the only difference is number of pins and where they are located + length of pins. I don’t draw in FreeCAD that often as I in most cases find very professional 3D parts and footprints on-line, but this will do.

What I do next is to create a test project where I mount the connectors and print the PCB on paper. As I have the actual connectors I test them to see if footprint and distances are correct. Hole-through are solid + in this case you also have a mounting to the panel.

GX16 is not adverticed as waterproof as it is a very robust aviation connector, but you can add rubber rings to make the socket itself waterproof. The plug is a bit more complicated as you need to buy waterproof versions (and they exist). The reward is a low cost waterproof connector. I considered other connectors like M8 and M12 series – I really like M12 series, but prices for M12 are up in 30 to 50 USD on some of the connectors.