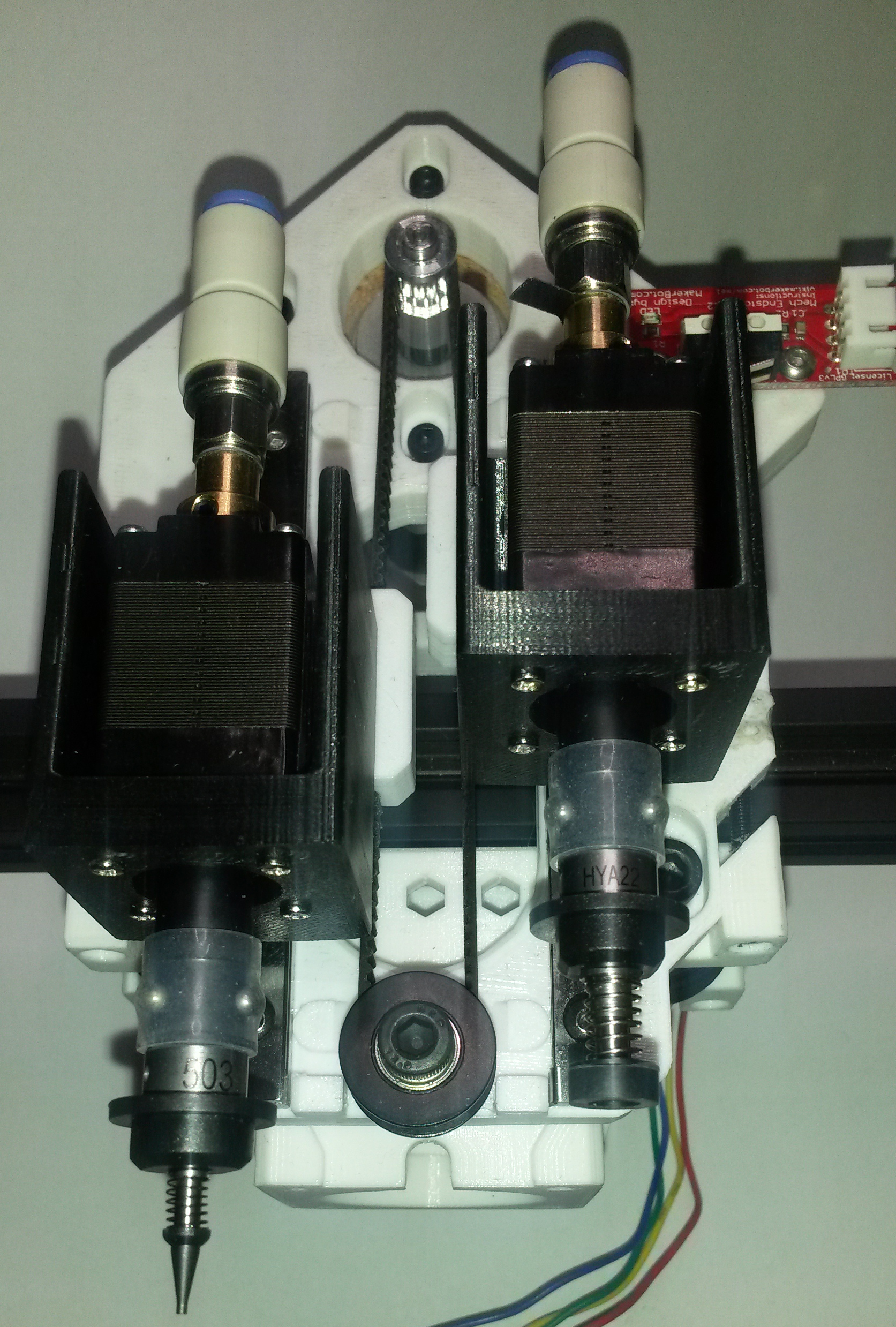

Finally got around to design holders for my Nema8 Nozzle head + I added a damper between the Nema17 and the head to reduce noise. I need to design tank-belt holders and I can start assembling pneumatic tubes and control system as I should have all parts by now.

I used FreeCAD to design these brackets. FreeCAD works, but it is a lot of bugs so you need some patience to use that in it’s current stage (version 0.20.2) – but, I am looking forward to new versions of FreeCAD + I need to learn more about it.

One of the things I want to do is to redesign the PnP Head completely. I work with Robotics as a profession and while this design is working I also see a lot of potential for mechanical improvements. As mentioned before I want to achieve 0201 quality and to do so I need to improve the mechanical accuracy/stability of the design. The white components above is PLA, while the black is PETG – a stronger type of plastic – but in the next design I want to avoid plastic on critical parts that will wear with movements. This is a machine with moving parts – it need to move fast and with some strength. The plastic design will work fine for a short period before it starts to wear out and not to mention that it will need constant adjustments. But, this is things you learn as you build one of these.

I also want a head with 4-8 nozzle tips on + I am very sceptical to the belt driven mechanism above – I suspect it will strugle with changing nozzle tips because you need some strength to click the on/off, but lets see. I will upload the changes I do to this machine, but contact me if you want them now.

I did notice that someone had dropped the adapter (in white) on top and made a non-turnable adapter – I will advice against that – that is 40.- USD that you do not want to save as the Nema8 will twist the pneumatic tubes and cause them to wear out fast.

Also remember that the z-gantry needs oiling from time to time.

The drawing above illustrate the current frame design with 4 x 2020 aluminum profiles (V type). I considered going up to 3030 or 2040 etc, but I do not have an issue with the strength of the profiles – I do hoverer have an issue with the entire frame moving a bit. So what I want to do is to double the width of the frame as follows:

This will increase the Y gantry to 1200 mm and stabilize the frame at the same time. To do so I only need to buy 3 x 2020 profiles that is 1200 mm long + 1 extra 600mm profile. I think this will do more for stability than adding larger profiles. Using the extra sis is an issue because I seldom need feeders – as most hobbyists I use strips and components in trays – I need the extra space to put this on and this is a low cost and very effective modification I think.