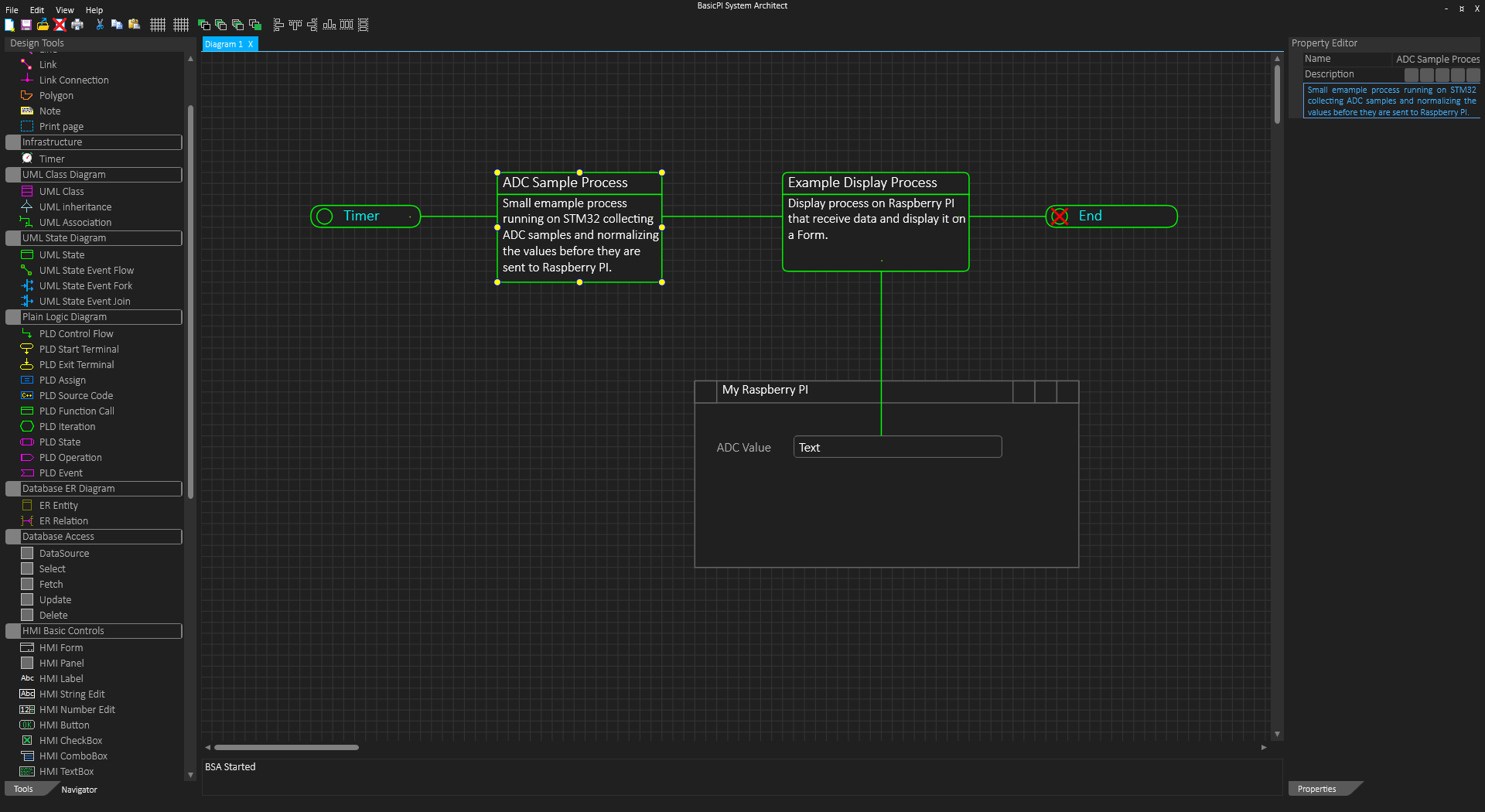

I will introduce a display symbol to do IO towards HMI so I don’t need copies of Forms everythere, but the diagram below is actually functional.

I could actually generate code based on this – the two processes are modules where one run on STM32 and the second on Raspberry PI. The first collect ADC samples, the second display the results on a form. High level diagrans will be more or less like this and can be used as specifications in front of customers. If you double click on “ADC Sample Process” you will either see actual source code, PScript, Python, C++ or a sub-diagram reprecenting the logic. It will be a few executable details, but doing this exact job will be about this easy.

Notice that unlike LabView or other similar tools we process events in proper diagrams where the user can mix code as he/she pleases. The actual modules can be whatever you need them to be.

I recently had the opportunity to work on competing solutions and the experience tells me that I am on the right track – I have made a lot of correct choises that you will feel the power of as you start working with BSA – and while competetive products cost ca 4000 USD per license this will be closer to 40.- USD in cost for commercial usage (free for open source) – and no dependency – if all you want to do is to use BSA to generate source code that you maintain manually – be my guest.

Stay tuned…