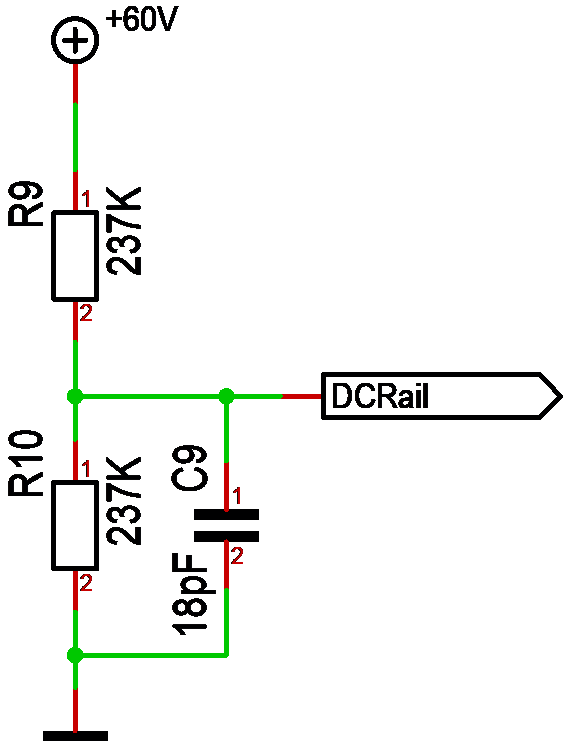

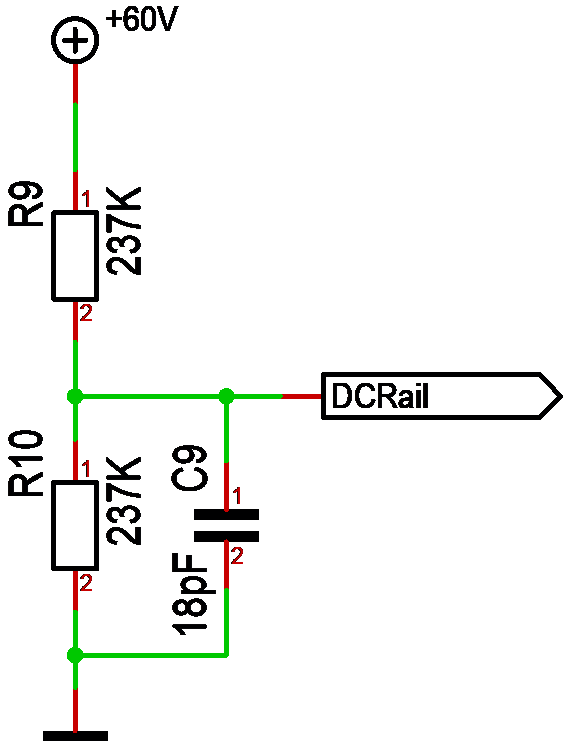

What I have done here is to draw the circuit for DC-Rail and copied 2 resistor values without changing them – doh. I also assembled according to this and testet 30V, meaning I have injected 15V on a 3.3V ADC port – hmmm – wonder if that still works  To make things even worse – I actually have a not connected this to a TVS despite that I have one spare. That said – I also realize that some of these mistakes are unavoidable because as an engineer you reach a level where you have worked so long on a design that the only way forward is to test and find out what works what needs improvement. Maybe you could (as some do) spend far more time in design and avoid these errors, but my observation is that if you attempt that aproach you only end up using more time in design. My aproach is to forward a design to prototype as fast as I can to drive progress, but you have to find your own formula – whatever works for you. This one was annoying because I should have seen it as I assembled the components and I have wasted a day on an unstable MCU.

To make things even worse – I actually have a not connected this to a TVS despite that I have one spare. That said – I also realize that some of these mistakes are unavoidable because as an engineer you reach a level where you have worked so long on a design that the only way forward is to test and find out what works what needs improvement. Maybe you could (as some do) spend far more time in design and avoid these errors, but my observation is that if you attempt that aproach you only end up using more time in design. My aproach is to forward a design to prototype as fast as I can to drive progress, but you have to find your own formula – whatever works for you. This one was annoying because I should have seen it as I assembled the components and I have wasted a day on an unstable MCU.

I fixed the resister, but the MCU is bust so I need to replace it.

I also discovered that removing even a resistor is close to impossible with the heat-sink on. So, at least the heat-sink work remarkably well. Mounting the heat-sink was required to test the mechanics, but I think I will continue without heat-sink and termal greace until we have a verified, working design.