PLC (Programmable Logic Controllers) have been around for years. It usually is a modular system of electronic boxes with IO capabilities that can be assembled into a system for automation purposes. PLC have 5 “standard” languages that are not really that much standard. The standards tend to serve as minimum list of features, but as the vendors add much proprietary stuff the PLC applications end up being very proprietary. Plain have a much higher possibility of actually being portable.

A PLC system cost a lot of money, but as making custom electronics and writing code in C/C++ cost more the vendors get away with high pricing on electronics, tools and HMI. Also – the hard fact is that it is not much I can do with a professional PLC that I can’t do better, faster and with less cost using Arduino or Raspberry PI these days.

I have briefly mentioned HMI – I will return to that later. But, my Raspberry PI Hat’s and RS-X modules powered by Plain is an excellent PLC substitute. I do however fancy a more dedicated, modular system that can compete with classic PLC in a smaller space. My Hat’s are great, but it’s limited what I can create on the size of a Hat + the Raspberry PI is often not needed. I want to keep the option to add a RPI module with a Hat, but I want a new system.

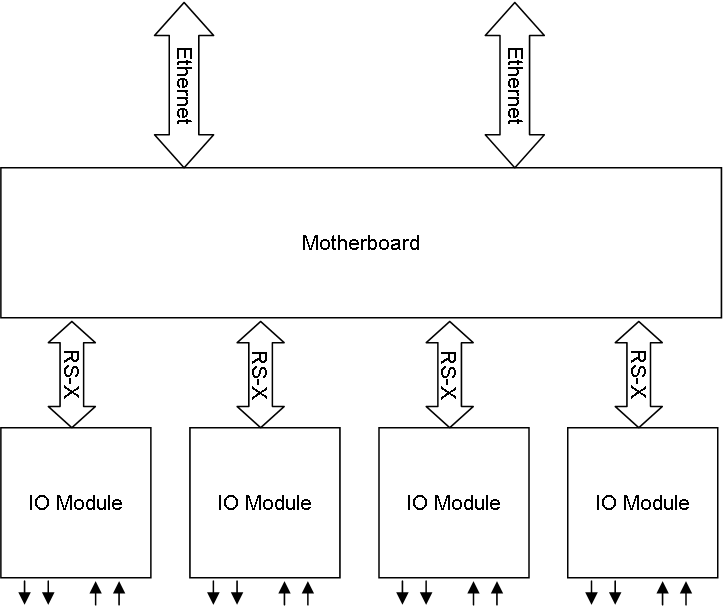

Using Ethernet as backbone I would like to create a motherboard that control 4 x IO modules. Using RS-X as bus allows me to use the modules stand-alone or plugged them into a assembled system. Adding more motherboards I can scale up with 4+4+4+ modules as much as I have space. I believe I can do this on very small Space.

The major restriction I have on the Hat’s is connector space. I want to use standard connectors with standard cabling to avoid the need for custom cabling as much as possible. My “PLC” language will obviously be Plain.

What needs to be different from what I have done so far is Galvanic Isolation on all communication to limit the chain reaction if something backfires – because it will!

The added work-load on coding does not worry me because we can re-use things that I am in the process of creating anyway + I think this will be fun. 10 x 10 cm comes to mind as a size factor. It is easy to create modules that are 5 x 10, 10 x 5 or 10 x 10 to be mounted as part of the same system so it gives us freedom. It is also easy to create a 10×10 carrier module for Raspberry PI so a RPI+ Hat’s can become a module. But, I will look for standard, low cost project boxes before I decide on size.

It will be fun if nothing else and thats why I am here in the first place, so lets crack on with an open source, home made, low cost PLC system. My home is an excellent testing ground – assuming it don’t burn to the ground in the process